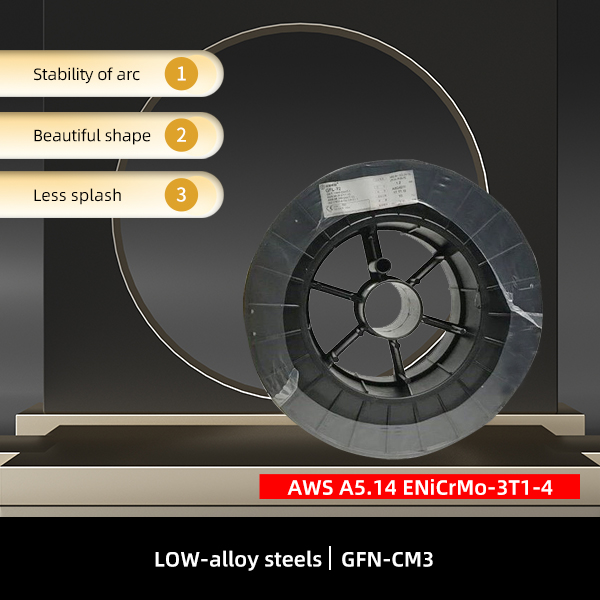

Nickel alloys Flux cored waya ENiCrMo3T1-4 Njikọ nkwado

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb | Mo | P | S |

| GB/T iwu | - | - | - | - | - | - | - | - | - | - |

| Iwu AWS | 0.10 | 0,50 | 0,50 | 20.0-23.0 | ≥58.0 | 5.00 | 3.15-4.15 | 8.0-10.0 | 0.02 | 0.02 |

| URU Ọmụmaatụ | 0.015 | 0.25 | 0.3 | 22 | 64.00 | 0.3 | 3.3 | 9.5 | 0,0005 | 0,0005 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | IMAPACT URU J/℃ | ELONGATION(%) | ||||

| GB/T iwu | - | - | - | - | ||||

| Iwu AWS | - | 690 | - | 25 | ||||

| URU Ọmụmaatụ | - | 760 | 80/-196 | 32 | ||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 1.2 | ||||

| Volt | 25-34 | ||||

| Amp | 150-250 | ||||

| Ogologo ndọtị akọrọ (mm) | 15-25 | ||||

| Orufe gas (l/min) | 20-25 | ||||

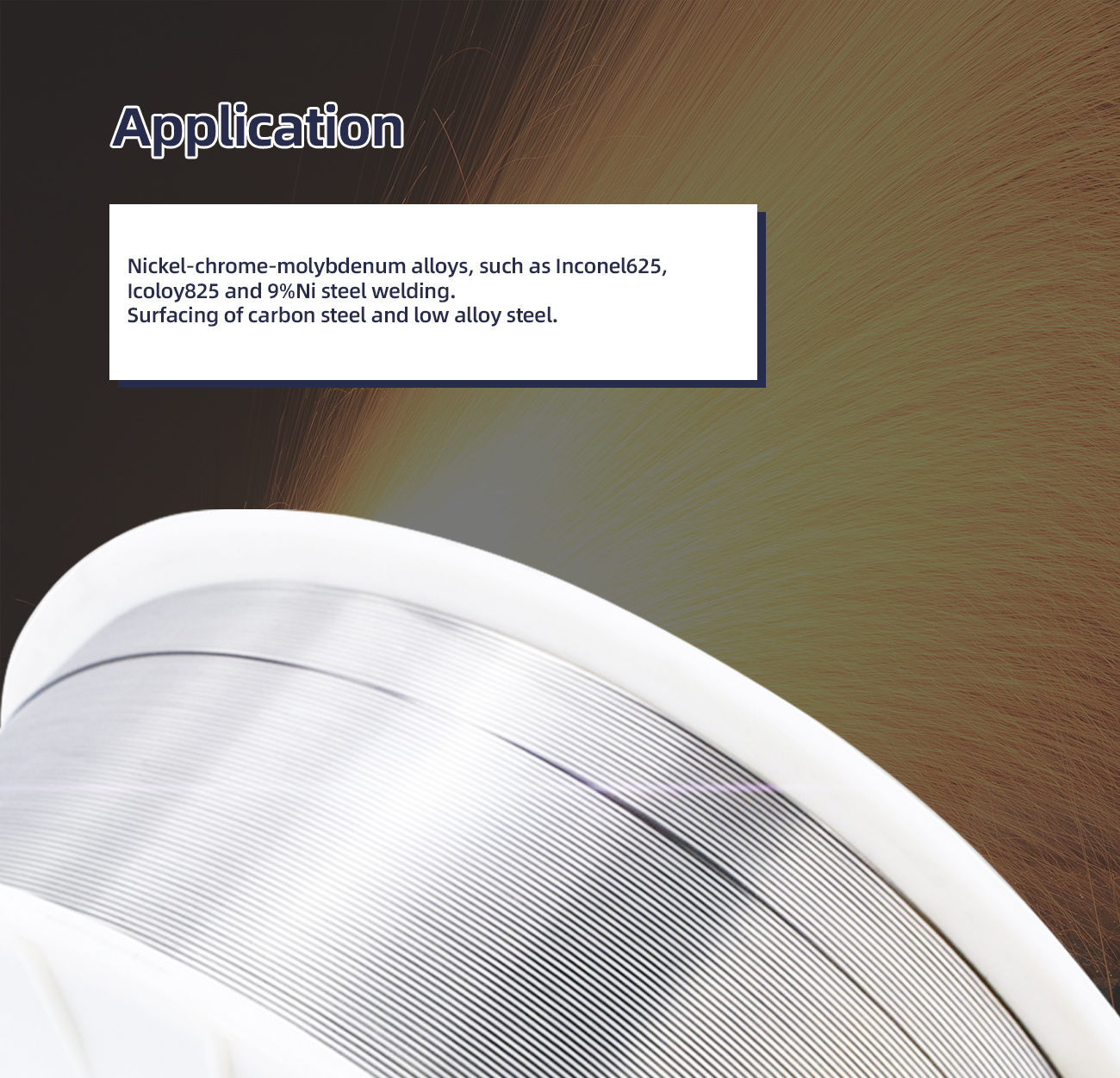

Ngwakọta ọnụ bụ 60%Ni-22%Cr-9%Mo-3%Fe-3.6%Nb.

-196°C arụ ọrụ mmetụta dị ala dị mma.

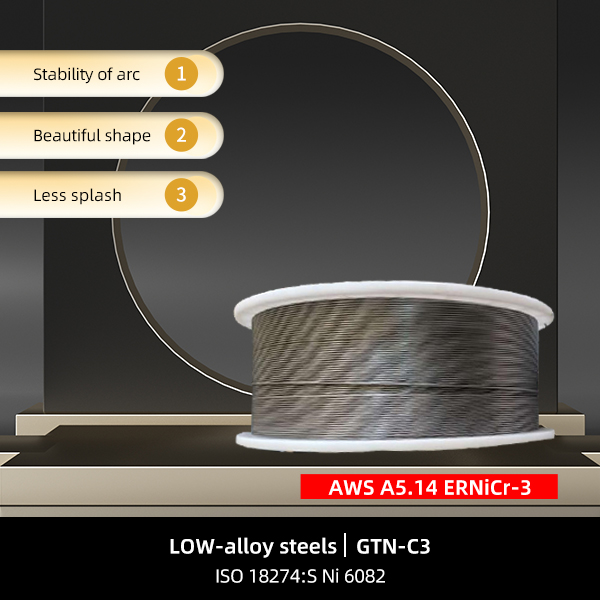

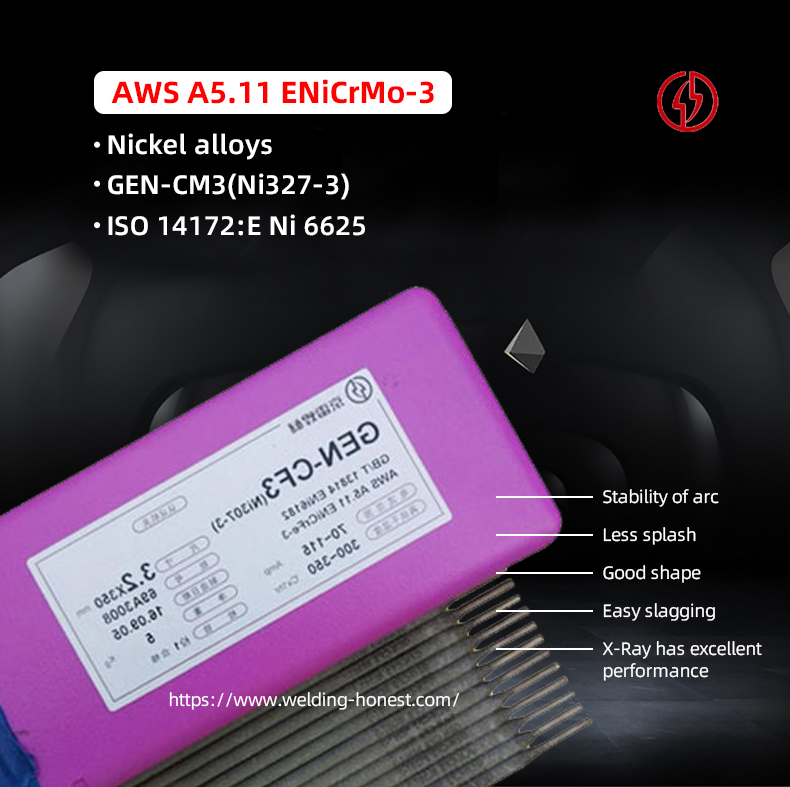

Akụ ahụ dị nro ma kwụsie ike, ọ na-adịchaghị agbasa, ọkpụ akpụ mara mma, mwepụ slag dị mma, nri waya kwụsiri ike, nwere ezigbo usoro ịgbado ọkụ.

-

Ngwa ike ọkụ

-

Qinghai Youjian Wunan Oilfield

-

20000TEU akpa ụgbọ mmiri

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb | Mo | P | S |

| GB/T iwu | - | - | - | - | - | - | - | - | - | - |

| Iwu AWS | 0.10 | 0,50 | 0,50 | 20.0-23.0 | ≥58.0 | 5.00 | 3.15-4.15 | 8.0-10.0 | 0.02 | 0.02 |

| URU Ọmụmaatụ | 0.015 | 0.25 | 0.3 | 22 | 64.00 | 0.3 | 3.3 | 9.5 | 0,0005 | 0,0005 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | IMAPACT URU J/℃ | ELONGATION(%) | ||||

| GB/T iwu | - | - | - | - | ||||

| Iwu AWS | - | 690 | - | 25 | ||||

| URU Ọmụmaatụ | - | 760 | 80/-196 | 32 | ||||

akwadoro welding paramitaS:

| Nkọwapụta DIAMETERS(mm) | 1.2 | ||||

| Volt | 25-34 | ||||

| Amp | 150-250 | ||||

| Ogologo ndọtị akọrọ (mm) | 15-25 | ||||

| Orufe gas (l/min) | 20-25 | ||||

Dee ozi gị ebe a ziga anyị ya