Nickel alloys akwụkwọ ntuziaka elektrọd ENi-1 weld imepụta

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Ni | Fe | Ti | Cu | P | S |

| GB/T iwu | 0.10 | 0.75 | 1.20 | ≥92 | 0.70 | 1.0-4.0 | 0.20 | 0.02 | 0.015 |

| Iwu AWS | 0.10 | 0.75 | 1.25 | ≥92 | 0.75 | 1.0-4.0 | 0.25 | 0.03 | 0.02 |

| URU Ọmụmaatụ | 0.046 | 0.06 | 0.82 | 95.5 | 0.12 | 2.7 | 0.01 | 0,007 | 0.001 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | IMAPACT URU J/℃ | ELONGATION(%) | ||||

| GB/T iwu | 200 | 410 | - | 18 | ||||

| Iwu AWS | - | 410 | - | 20 | ||||

| URU Ọmụmaatụ | 310 | 435 | - | 29 | ||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||||

| ELECTRICITY (Amp) | H/W | 65-95 | 70-115 | 95-145 | ||||||

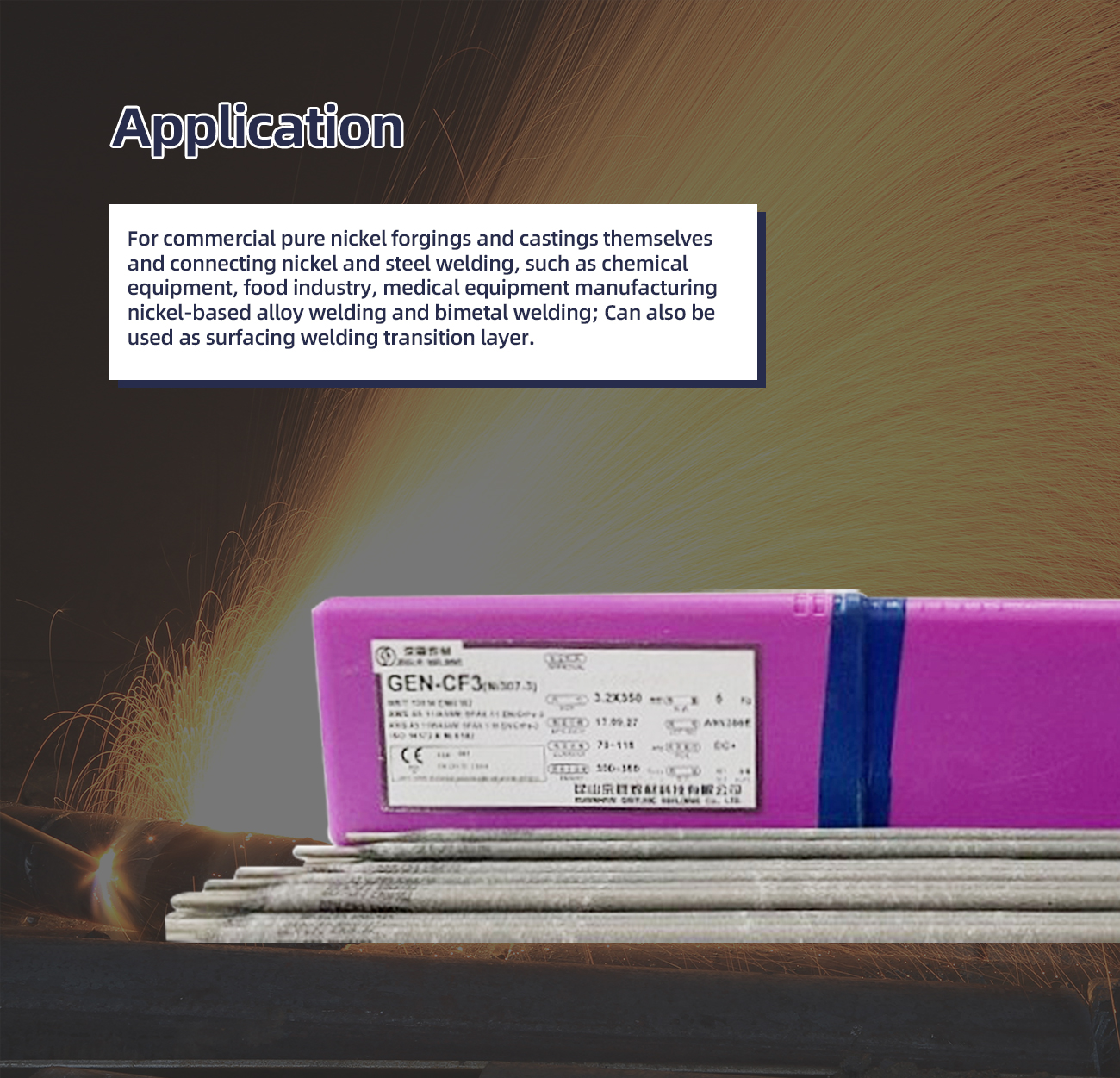

Titanium-calcium electrode aka, ihe mejupụtara ọnụ (pasent n'ịdị arọ) bụ 95Ni-2.5Ti.

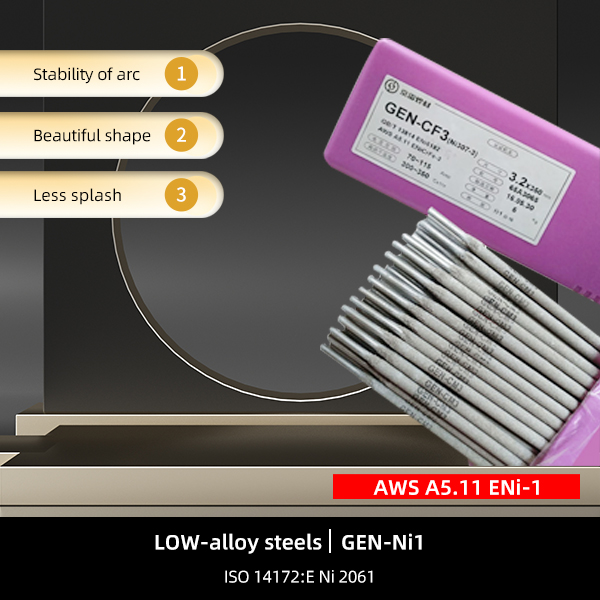

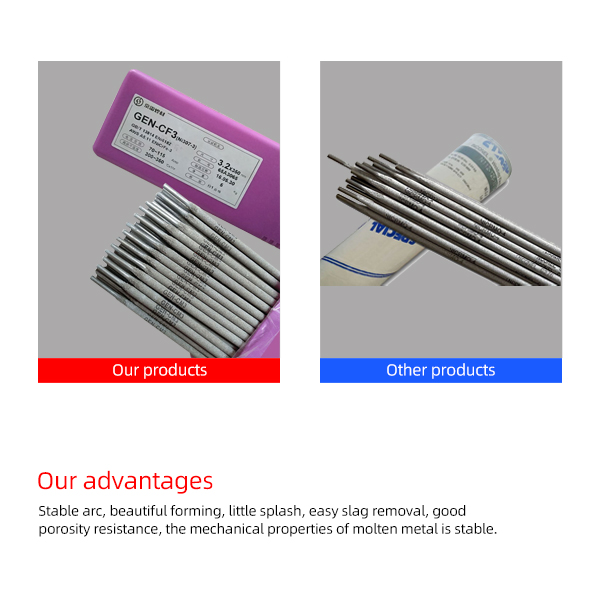

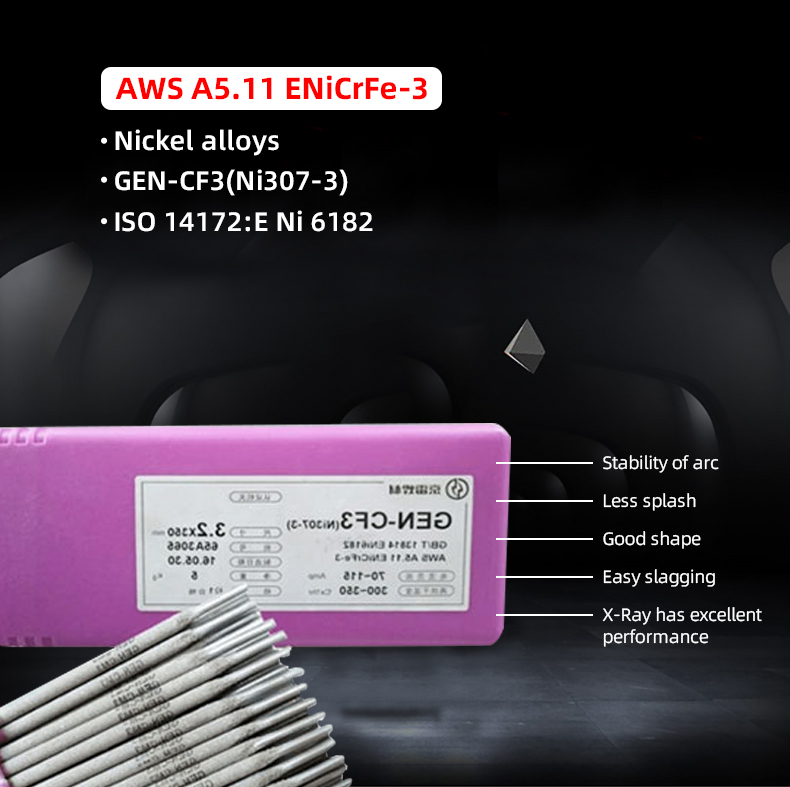

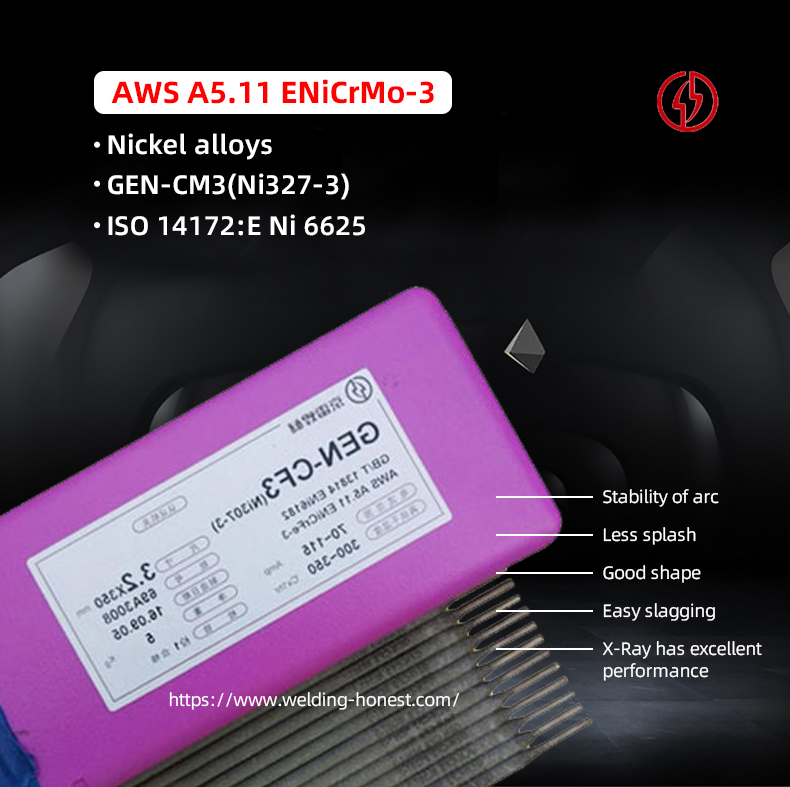

Arc kwụsiri ike, nhazi mara mma, obere mkpọsa, mwepụ slag dị mfe, ezigbo nguzogide porosity.

Igwe ejikọtara ọnụ nwere ezigbo ihe eji arụ ọrụ, nguzogide okpomọkụ, nguzogide corrosion, ngwakọta na mgbape mgbape.

Cr-Mo steel usoro ịgbado ọkụ ihe na electrode surfacing ihe ịgbado ọkụ ka a na-ejikarị na akụrụngwa na-anụcha mmanụ ala.

-

158,000 tọn Suez tanker

Supercore SG

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Ni | Fe | Ti | Cu | P | S |

| GB/T iwu | 0.10 | 0.75 | 1.20 | ≥92 | 0.70 | 1.0-4.0 | 0.20 | 0.02 | 0.015 |

| Iwu AWS | 0.10 | 0.75 | 1.25 | ≥92 | 0.75 | 1.0-4.0 | 0.25 | 0.03 | 0.02 |

| URU Ọmụmaatụ | 0.046 | 0.06 | 0.82 | 95.5 | 0.12 | 2.7 | 0.01 | 0,007 | 0.001 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | IMAPACT URU J/℃ | ELONGATION(%) | ||||

| GB/T iwu | 200 | 410 | - | 18 | ||||

| Iwu AWS | - | 410 | - | 20 | ||||

| URU Ọmụmaatụ | 310 | 435 | - | 29 | ||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | |||||||

| ELECTRICITY (Amp) | H/W | 65-95 | 70-115 | 95-145 | ||||||