Whatsapp:+8613252436578 E-mail:sale@welding-honest.com

1. nhazi ọkwa

Dị ka ọnụ ọgụgụ nke carbon ọdịnaya, carbon ígwè nwere ike kewaa n'ime atọ ndị a:

1) obere carbon ígwè C% ≤ 0.25

2) Ọkara carbon ígwè 0.25

3) Elu carbon ígwè C%> 0.6

Katọn dị ala

Carbon etiti

Carbon dị elu

2. weldability analysis

Ọnụ ego nke carbon bụ ihe dị mkpa maka mmepe nke usoro ịgbado ọkụ. Ka carbon ọdịnaya na-abawanye, ike na ike na-abawanye, ebe plasticity na ike na-ebelata, ebe nrụgide na-abawanye. N'ikwu ya n'ụzọ dịtụ, obere carbon ọdịnaya, ka mma weldability, ya mere, carbon ọdịnaya bụ ụkpụrụ maka ikpe ihe isi ike nke carbon ígwè ịgbado ọkụ, na dị iche iche ịgbado ọkụ usoro kwesịrị ịnakwere maka iche iche carbon ọdịnaya.

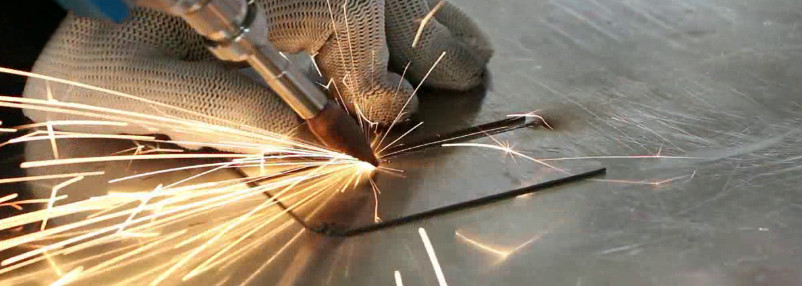

3. Usoro ịgbado ọkụ

Nhọrọ nke carbon steel ihe ịgbado ọkụ na-agbaso ụkpụrụ nke "ike nha anya"

1. Obere carbon ígwè (a maara nke ọma dị ka nwayọọ ígwè)

Akara akara nchara dị ka Q235 (nke a na-akpọkarị A3 steel), Q255, wdg, anaghị ewere usoro pụrụ iche mgbe ịgbado ọkụ, ọ bụghị ikpo ọkụ ma ọ bụ postheating.

2. Ọkara carbon ígwè

A na-ejikarị ígwè eme ihe dị ka 30 #, 45 #, wdg, 45 # bụ ihe eji eme ihe maka ịmepụta agụba na faịlụ, ọ kacha mma iji ihe mgbado ọkụ na-adịghị ala ala nwere ezigbo nkwụsị mgbape, preheating 100-200 °C; Ọ bụrụ na ọ naghị adabara ikpo ọkụ, Cr-Ni austenitic igwe anaghị agba nchara nwere ike ịhọrọ.

3. Elu carbon ígwè

Akara akara igwe a na-ejikarị dịka 60Si2Mn, T8, T10 na ndị ọzọ. 60Si2Mn bụ igwe mmiri a na-ahụkarị, n'ozuzu anaghị eme ọgwụgwọ ịgbado ọkụ, nke a na-ejikarị dị ka ịgbado ọkụ, kwesịrị ịdị 250-350 Celsius C preheating, ịgbado ọkụ ga-emerịrị iji kpochapụ nrụgide, yana 650 Celsius C ọgwụgwọ ọkụ ọkụ. họrọ Cr-Ni austenitic igwe anaghị agba nchara ihe

Nke anọ, ihe dị mkpa nke ịgbado ọkụ nchara nchara:

Electrode ihicha okpomọkụ

| Ihe | Ụdị akpụkpọ ahụ | Ngwaahịa | Okpomọkụ | Oge |

| Igwe carbon dị ala na ígwè dị elu | Ụdị hydrogen dị ala | E7016, E7048, E7015, E7015-G | 300-350 ℃ | Nkeji 60 |

| E7015, E8015-G, E9016-G, E9015-D1, E10015-D2, E12015-G | 330-380 ℃ | |||

| Nnukwu ike na ụdị hydrogen dị ala | E7016-G, E7015-G, E8015-G, E9015-G, E10015-G | 350-380 ℃ | Nkeji 60 | |

| Iron ntụ ntụ obere hydrogen ụdị | E7018, E7018-1 | 300-350 ℃ | Nkeji 60 | |

| E8018-G, E918-G, E9018-M, E10018-D2, E10018M, E11018-G, E11018M, E12018-G | 350-380 ℃ | Nkeji 60 |

2. Ekwesịrị iwepụ mmiri mmiri, mmanụ, nchara, wdg n'elu ihe isi ala

3. Jiri usoro azụ azụ wee weld iji zere stomata na mmalite

Ekwesịrị iji obere ịgbado ọkụ dị mkpụmkpụ, dị ka ibe oscillating, na njupụta oscillation ekwesịghị gafere 3 ugboro dayameta waya.

Oge nzipu: Ọktoba 13-2022