Tower na-eji maka distillation, ọcha, absorption, distillation na ndị ọzọ chemical ngwá, ọtụtụ n'ime ụlọ elu ngwaọrụ mkpa ịkpọtụrụ acid, alkali, nnu, organic solvents na ndị ọzọ corrosive media, n'ihi ya, ọ dị mkpa ka surfacing a nnukwu ebe corrosion eguzogide oyi akwa. na cylinder na akụkụ akara. Dị ka ụzọ na-arụ ọrụ nke ọma nke surfacing, warara surfacing na-ọtụtụ ebe na ụlọ elu ịgbado ọkụ nke kemịkalụ akụrụngwa.

The omenala electrode surfacing technology bụ okpukpu abụọ-layer submerged arc surfacing technology na mgbanwe oyi akwa na corrosion eguzogide oyi akwa, ma a technology nwere ogologo n'ichepụta okirikiri na elu n'ichepụta ego. Iji dozie nsogbu a, JingQunCo emepụtala ihe ịgbado ọkụ nke otu oyi akwa (GDS-309LA welding strip, GXS-ED308L electroslag flux), nke nwere ike nweta mmetụta nke elu elu nke okpukpu abụọ na naanị otu oyi akwa, ma nwee ike ime ka ọ dị mfe. usoro nlegharị anya site na elu nke okpukpu abụọ ruo otu oyi akwa.

Okwu mmalite nke ihe ịgbado ọkụ

1.The Chemical akụrụngwa

| Rules/aha | C | Si | Mn | P | S | Cr | Ni | Note |

| NB/T47018.5 EQ309LA | ≤0.030 | ≤1.00 | 0.5-2.5 | ≤0.025 | ≤0.015 | 21.0-23.0 | 9.0-12.0 | warara solder |

| GDS-309LA | 0.018 | 0.34 | 1.90 | 0.017 | 0.001 | 21.96 | 11.17 | warara solder |

| Rules/aha | NB/T47018.5 FZ308-D | GDS-309LA+GXS-ED308L Ihe nchikota solder strip+ Flux | |||

| C | ≤0.05 | 0.028 | 0.028 | 0.029 | 0.029 |

| Si | ≤1.00 | 0.58 | 0.64 | 0.62 | 0.64 |

| Mn | ≤2.5 | 1.33 | 1.33 | 1.35 | 1.33 |

| P | ≤0.030 | 0.018 | 0.018 | 0.018 | 0.017 |

| S | ≤0.020 | 0,004 | 0,004 | 0,004 | 0,004 |

| Cr | 18.0-21.0 | 18.21 | 18.47 | 18.39 | 18.28 |

| Ni | 8.0-11.0 | 10.12 | 10.31 | 10.27 | 10.30 |

| Rịba ama | ọla edo edo | N'elu ịgbado ọkụ | N'okpuru elu 1mm | N'okpuru elu 2mm | N'okpuru elu 3mm |

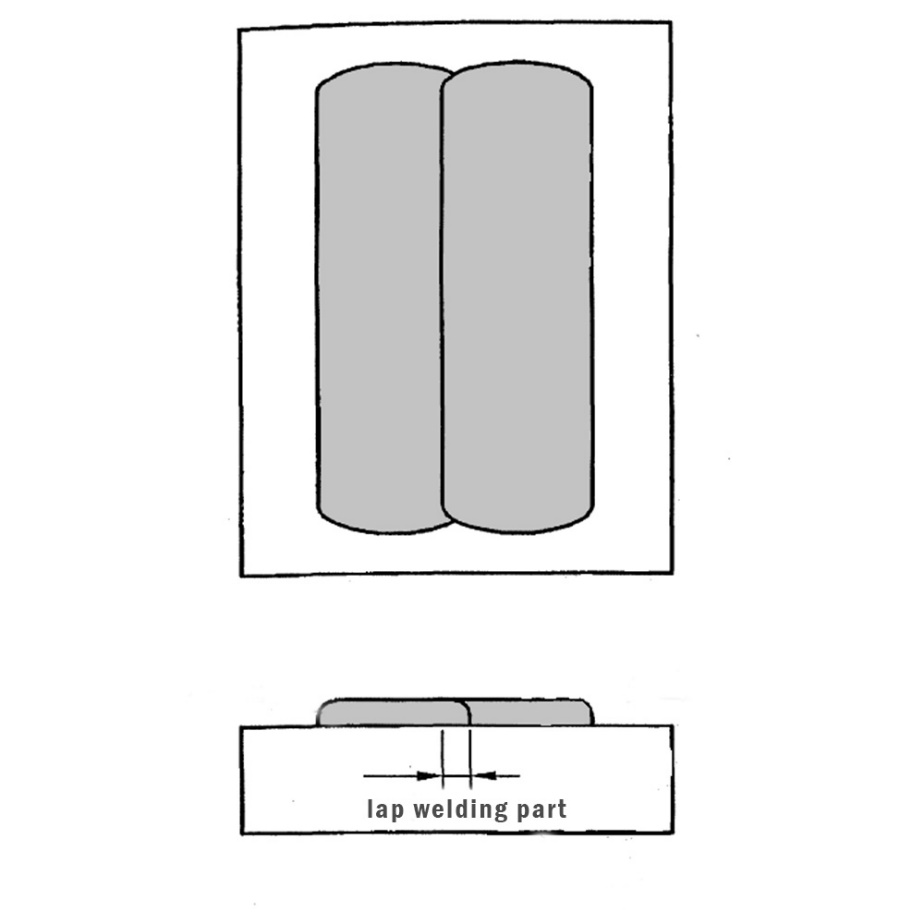

2.Weld ọdịdị

Oke ịgbado ọkụ akwadoro

| Nkọwa (mm) | 0.5*60 |

| Eletrik(A) | 850-950 |

| Voltaji(V) | 26-30 |

| WỌsọ elding (mm/min) | 150 |

| Logologo (mm) | 35-40 |

| Agbadokwa ụkwụ (mm/min) | 6-10 |

| Ọkpụrụkpụ nke mgbasa mgbasa (mm/min) | Ankeji 25 |

Weld ngafe ọkpụrụkpụ: banyere 4.7mm

Weld obosara: banyere 62.5mm

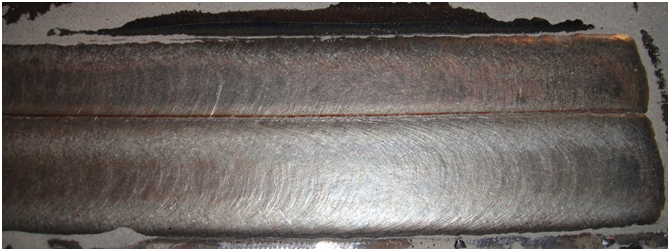

Weld ngafe ọdịdị: ọmarịcha udi, weld elu bụ larịị, n'apata mgbanwe bụ ezigbo.

3.Mechanical ikike

Ọdịnaya ferrite (steeti welded)

| Nchikota solder strip+ Flux | GDS-309LA+GXS-ED308L |

| Uru atụnyere | Ọdịnaya ferrite bụ ihe dịka 7FN, yana ọdịnaya pasent ferrite bụ ihe dịka 8% |

| Ọnọdụ nha | Weld elu |

Ule ule: GB/T 1954-2008 "chromium-nickel austenitic igwe anaghị agba nchara weld ferrite ọdịnaya usoro"

Nnwale ịgbagọ:

as

620 ℃ * 20h

Nsonaazụ ule: mpụta mpụta, indenter dayameta 4T (40mm), ekwe Angle 180° na-enweghị mgbape.

Nnwale corrosion intergranular

Dị ka welded

620 ℃ * 20h

Usoro nnwale: GB/T 4334-2020 Usoro E

Ngwọta ule: ọla kọpa - ọla kọpa sulfate -16% sulfuric acid

Nsonaazụ ule: Enweghị mgbawa corrosion intergranular

Micro metallography nke surfacing oyi akwa

Dị ka welded

Dị ka welded

620 ℃ * 20h okpomọkụ ọgwụgwọ

620 ℃ * 20h okpomọkụ ọgwụgwọ

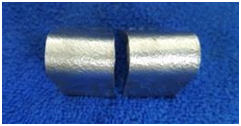

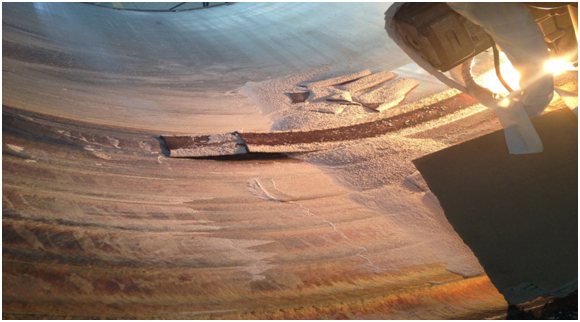

Ngwa injinia

Usoro nyocha usoro ịgbado ọkụ 1.Customer

2.Customer saịtị ewu

Mgbe ọtụtụ afọ nke nnyocha na mmepe, Jingqun single-layer electroslag surfacing welding material performance is stable and trust, has many engineering ngwa rụzuru.

Nabata ndị ahịa ka ị kpọtụrụ ma họrọ!

Ozi ndi ozo tinye whatsapp+86 13252436578

E-Mail:sale@welding-honest.com

Oge nzipu: Nov-04-2022