Na 2010, South Korea's POSCO, Daewoo Shipbuilding na ụwa ise isi nhazi ọha mmadụ malitere oru ngo nke "njikọ mmepe nke elu manganese ígwè na ịgbado ọkụ ihe maka ultra-obere okpomọkụ", na nweta uka mmepụta nke elu manganese ígwè maka LNG nchekwa tankị. 2015. Site na June 2022, imebi site na teknụzụ teknụzụ, South Korea's Daewoo Shipbuilding & Marine Engineering (DSME) na POSCO ga-ejide nke mbụ n'ụwa iji wụnye tankị nchekwa mmanụ dị elu nke manganese ígwè LNG na mmemme nnukwu ndị na-ebu ibu (VLCC) nke LNG kwadoro, ma kwuo na ọ zụlitere nkà na ụzụ nrụpụta mmanụ ụgbọala site na nhazi ígwè. ka ịgbado ọkụ na akpụ.

1. Gịnị bụ nnukwu manganese ígwè?

Igwe manganese dị elu maka tankị nchekwa LNG bụ ọla alloy nwere ọdịnaya manganese dị n'etiti 22-25%, nke nwere ezigbo nguzogide okpomọkụ dị ala na nguzogide dị elu, nke pụtara ìhè karịa ihe nchekwa nchekwa LNG ọdịnala Ọ bụ ọmarịcha ọmarịcha tankị nchekwa LNG. ihe ndị South Korea nyefere na nyocha na mmepe ihe karịrị afọ iri.

2.Brief nyocha nke ụdị nchara na uru ha na ọghọm ha maka tankị nchekwa LNG Ngwa anyị na-eji agbado ọkụ nwere ike imezu ihe ndị a siri ike: Ebe ọ bụ na nnukwu tankị nchekwa mmanụ LNG bụ ihe bụ isi nke ụgbọ mmiri na-arụ ọrụ gburugburu ebe obibi na gburugburu ebe obibi na ụlọ ọrụ LNG dum. ụkpụrụ teknuzu ndị siri ike na ọnụ ahịa dị oke ọnụ. A na-echekwa ma bufee LNG n'okpuru ọnọdụ okpomọkụ dị ala nke -163°C. A na-akpọ "koodu mba ụwa maka owuwu na akụrụngwa nke ụgbọ mmiri na-ebuga gas na nnukwu nnukwu" dị ka "IGC Code". Ihe anọ dị ala nke nwere ike iji rụọ ọrụ LNG gụnyere: aluminum alloy steel, Austria Tensitic igwe anaghị agba nchara, austenitic Fe-Ni alloy steel (nke a makwaara dị ka Invar steel) na 9% Ni steel (lee Isiokwu 1 maka nkọwa). ebe 9% Ni ígwè bụ nke a na-ejikarị na nke a na-ejikarị eme ihe maka tankị nchekwa mmanụ ọkụ LNG. Ma ihe ndị na-adịghị mma bụ na ọnụahịa ahụ ka dị elu, usoro nhazi ahụ na-agwụ ike, ike dị ntakịrị, na ọdịnaya nickel dị na ngwaahịa ahụ dị elu. N'ime afọ ndị na-adịbeghị anya, ọnụ ahịa nickel nọgidere na-arị elu, ọnụ ahịa ngwaahịa abawanyela nke ukwuu.

Ihe 4 cryogenic nwere ike iji na-ewu LNG n'okpuru "Iko IGC"

| Okpomọkụ imewe kacha nta | Ụdị ígwè isi na ọgwụgwọ okpomọkụ | Okpomọkụ ule mmetụta |

| -165 ℃ | 9% Ni ígwè NNT ma ọ bụ QT | -196 ℃ |

| austenitic igwe anaghị agba nchara - 304, 304L, 316/316L, 321 na 347 ngwọta na-emeso. | -196 ℃ | |

| Aluminom alloy - 5083 annealed | NO | |

| austenitic ígwè-nickel alloy (36% Ni) |

Ntụnyere ike n'etiti ihe LNG a na-ejikarị na ígwè manganese ọhụrụ dị elu

| Ihe | Alloy na-emekarị | nnukwu manganese ígwè | ||||

| 9% bụ ígwè | 304 SS | Alu 5083-O | Invar ígwè | MC | ||

| Ihe ndabere | Ngwakọta kemịkalụ | Fe-9Ni | Fe-18.5Cr-9.25Ni | Al-4.5Mg | Fe-36Ni | M CH nde |

| Microstructure | α1 (+Y) | (FCC) | FCC | FCC | FCC | |

| Mpụta IkeMpa | ≥585 | ≥205 | 124-200 | 230-350 | ≥400 | |

| Ike ọdụdọ Mpa | 690-825 | ≥515 | 276-352 | 400-500 | 800-970 | |

| -196 ℃MmetụtaJ | ≥41 | ≥41 | NO | NO | ≥41 | |

| Weldments | welding consumables | Inconal | Ụdị308 | ER5356 | - | FCA, SA, GTA |

| Mpụta IkeMpa | - | - | - | - | ≥400 | |

| Ike ọdụdọMpa | ≥690 | ≥550 | - | - | ≥660 | |

| -196 ℃MmetụtaJ | ≥27 | ≥27 | - | - | 27 | |

Ultra-obere okpomọkụ elu-manganese ígwè, nke na-ejikọta ike dị elu, ịdị elu siri ike, na ọnụ ala dị ala, nwere atụmanya ngwa ngwa n'ọdịnihu LNG tank tank na nchekwa gburugburu ebe obibi ọzọ ahịa nchekwa tank mmanụ dị ka mmiri mmiri amonia, mmiri mmiri hydrogen, na methanol.

Ngwakọta na arụmọrụ chọrọ nke nnukwu manganese ígwè

Ihe mejupụtara kemịkalụ (ASTM Draft)

|

| C | Mn | p | s | Cr | Cu |

| % | 0.35-0.55 | 22.5-25.5 | 00.03 | 00.01 | 3.0-4.0 | 0.3-0.7 |

Omume igwe

● Ọdịdị kristal: lattice cubic gbadoro ụkwụ na ihu (γ-Fe)

● Okpomọkụ ekwenyere -196℃

● Mpụta ike · 400MPa (58ksi)

● Ike nkwụsị: 800 ~ 970MPa (116-141ksi)

● Charpy V-notch mmetụta ule>41J na -196℃(-320℉)

Okwu mmalite nke nnukwu manganese ígwè dakọtara nke ụlọ ọrụ anyị

N'ime afọ ndị na-adịbeghị anya, anyị etinyela onwe anyị na nyocha na mmepe nke nnukwu manganese ígwè na-ejikọta ihe ịgbado ọkụ maka tankị nchekwa LNG, wee mepụta nke ọma ihe eji eme ihe na-agbado ọkụ nke nwere ike dakọtara na njirimara nke nnukwu manganese ígwè isi ihe maka tankị nchekwa LNG. E gosipụtara ihe ndị a kapịrị ọnụ na Tebụl 2.

Mechanical Njirimara nke nnukwu manganese ígwè kenha ịgbado ọkụ consumables edebe metal

| Aha | Ọnọdụ | n'ibu Njirimara | ||||

| YP | TS | EL | -196 ℃ mmetụta | ule redio | ||

| Ihe mgbaru ọsọ chepụta | ≥400 | ≥660 | ≥25 | ≥41 | I | |

| GER-HMA Φ3.2mm | Eletrọd ntuziaka | 488 | 686 | 46.0 | 73.3 | I |

| GCR-HMA-S Φ3.2mm | Igwe eriri igwe | 486 | 700 | 44.5 | 62.0 | I |

Ps.Metal ntụ ntụ isi submerged arc ịgbado ọkụ waya maka elu manganese ígwè adopts dakọtara flux GXR-200 maka elu manganese ígwè.

Weldability na ngosi ihe atụ nke ihe eji agbado ígwè manganese dị elu maka tankị nchekwa LNG

E gosipụtara weldability nke welding consumables maka elu manganese ígwè dị ka ndị a

Electrode (GER-HMA) ewepụghị fillet ịgbado ọkụ mgbe slag wepụ

Electrode (GER-HMA) nkuku elu ịgbado ọkụ mgbe ewepu slag

Mkpanaka ịgbado ọkụ (GER-HMA) tupu na mgbe fillet ịgbado ọkụ slag mwepụ

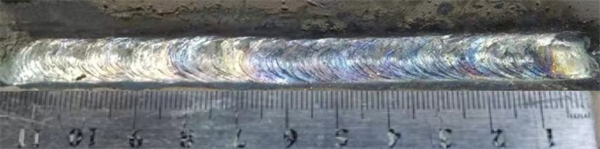

Metal powder core submerged arc (GCR-HMA-S) weld ngosi

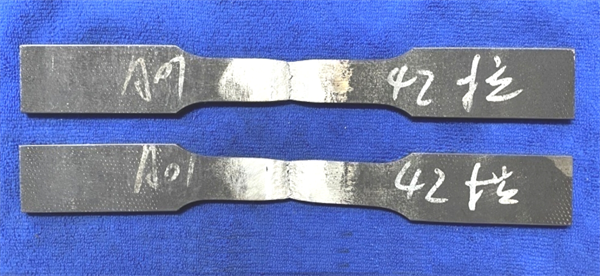

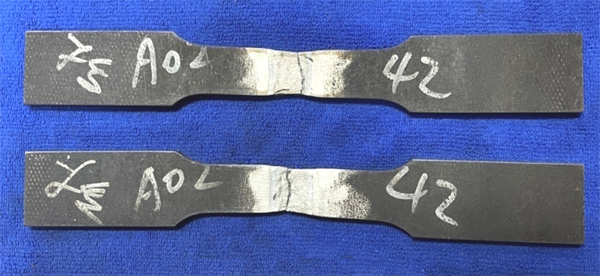

A na-egosi ihe atụ nke nnukwu manganese ígwè ịgbado ọkụ n'ikuku mkpara ịgbado ọkụ dị ka ndị a

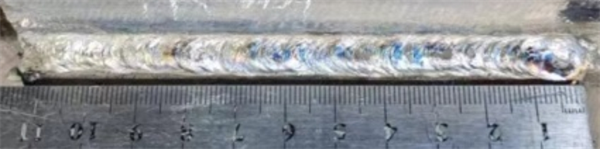

Ngosipụta nlele ịgbado ọkụ dị larịị (1G).

Ngosipụta nlele ịgbado ọkụ kwụ ọtọ (3G).

Ngosipụta nlele ịgbado ọkụ dị larịị (1G).

Ngosipụta nlele ịgbado ọkụ dị larịị (1G).

PS.High manganese ígwè na-welded na ịgbado ọkụ mkpara 1G na 3G, ọ dịghị cracks na ihu ekwe na azụ ekwe samples, na mgbape eguzogide dị mma.

Oge nzipu: Nov-22-2022