N'oge usoro siri ike, mgbawa na-ebutekarị nsogbu dị ka ịrụgharị ọrụ na nlọghachi ndị ahịa. Hardfacing surfacing dị iche na izugbe structural ịgbado ọkụ, na ikpe na anya direction nke cracks dịkwa nnọọ iche. Edemede a na-enyocha ma na-atụle ụdị mgbawa na-adịkarị na usoro nke ịnya elu na-eguzogide iyi.

1. Mkpebi nke mgbawa

Ka ọ dị ugbu a, n'ime ụlọ na ọbụna na mba ụwa, ọ dịghị ọkọlọtọ n'ozuzu maka mgbawa na-akpata site na ike elu elu. Isi ihe kpatara ya bụ na e nwere ọtụtụ ụdị ọrụ ọnọdụ maka ike elu eyi ngwaahịa, na ọ siri ike kọwaa dị iche iche Ọdabara mgbape ikpe ibiere n'okpuru ọnọdụ. Otú ọ dị, dị ka ahụmahụ na ngwa nke ike na-eche ihu na-eguzogide ihe ịgbado ọkụ n'ubi dị iche iche, ọtụtụ mgbape degrees nwere ike roughly hazie, nakwa dị ka ụkpụrụ nnabata na dị iche iche ụlọ ọrụ:

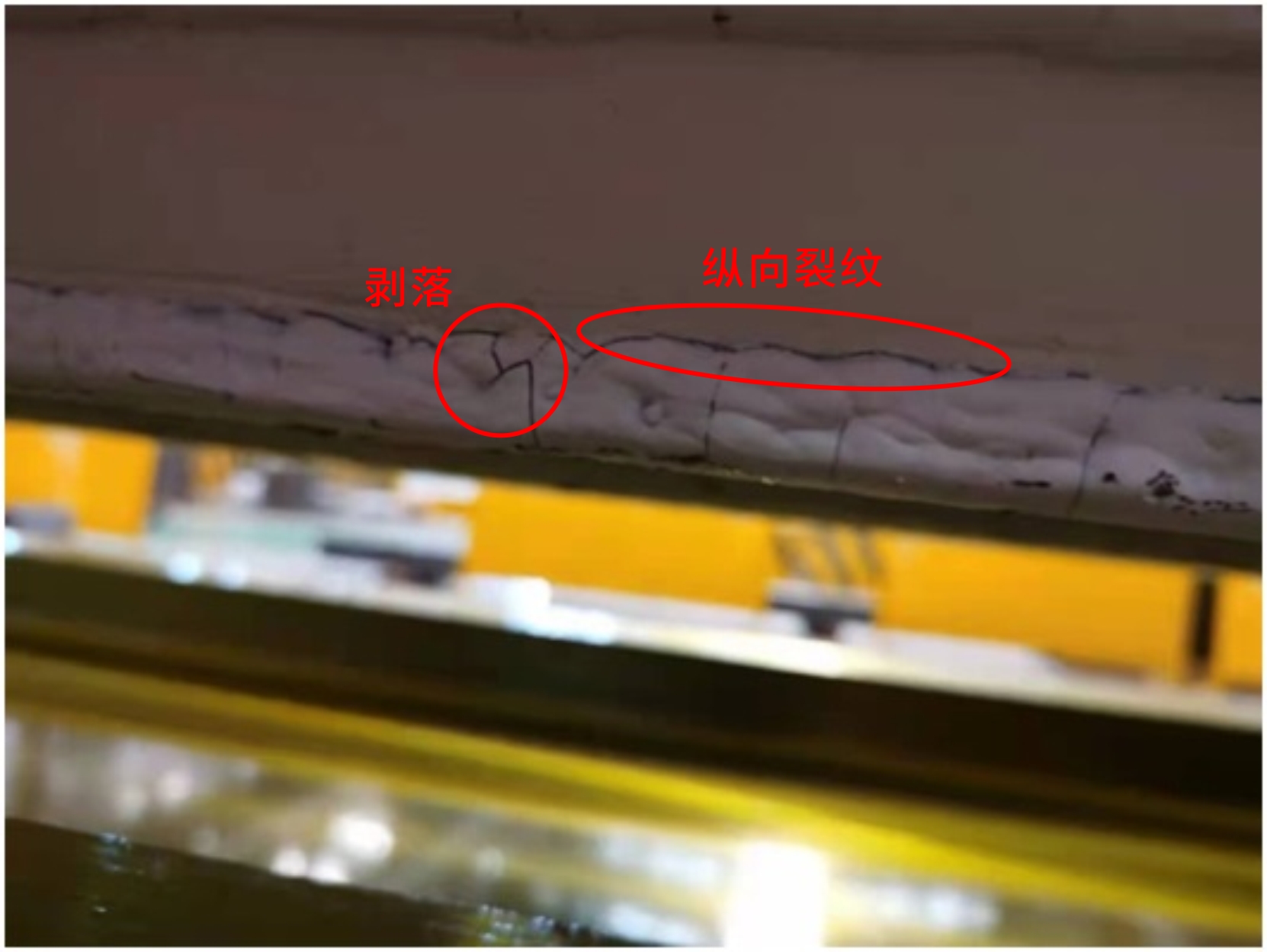

1. The ntụziaka nke mgbape bụ yiri weld bead (longitudinal mgbape), na-aga n'ihu transverse mgbape, mgbape ịgbatị na isi metal, spalling.

Ọ bụrụhaala na otu n'ime ọkwa mgbawa ahụ a kpọtụrụ aha n'elu zutere, enwere ihe ize ndụ na oyi akwa ahụ dum ga-adapụ. N'ụzọ bụ isi, n'agbanyeghị ihe ngwa ngwaahịa bụ, ọ bụ ihe a na-anabataghị na enwere ike ịmegharị ya ma regharịa ya.

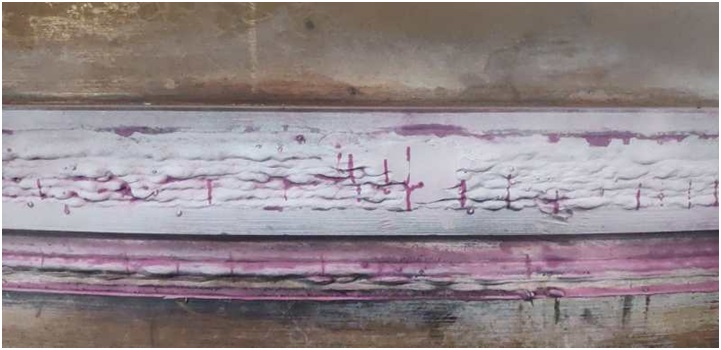

2. E nwere nanị transverse cracks na nkwụsị

N'ihi na workpieces na kọntaktị na ihe siri ike dị ka ore, sandstone, na coal mines, ike siri ike na-achọrọ ịdị elu (HRC 60 ma ọ bụ karịa), na elu-chromium ịgbado ọkụ ihe na-adịkarị eji maka surfacing ịgbado ọkụ. A ga-emepụta kristal chromium carbide nke emere na bead weld n'ihi ntọhapụ nrụgide. A na-anabata mgbapeka ma ọ bụrụhaala na ntụziaka mgbape ahụ dị naanị n'akụkụ weld bead (transverse) ma kwụsị. Otú ọ dị, ọnụ ọgụgụ nke cracks ka ga-eji dị ka ntụaka iji tụnyere uru na ọghọm dị na ịgbado ọkụ consumable ma ọ bụ surfacing usoro.

3. Enweghị mgbape weld bead

N'ihi na workpieces dị ka flanges, valves, na ọkpọkọ, ebe ndị bụ isi kọntaktị ihe bụ gas na mmiri mmiri, ihe ndị a chọrọ maka cracks na weld bead na-akpachara anya karị, na ọ na-achọkarị na ọdịdị nke weld bead ekwesịghị inwe cracks.

Ọ dị mkpa ịrụzi ma ọ bụ rụgharịa ntakịrị mgbawa n'elu ihe arụ ọrụ dị ka flanges na valves.

Jiri valvụ GFH-D507Mo nke ụlọ ọrụ anyị ihe eji agbado ọkụ pụrụ iche maka ịnya elu, enweghị mgbawa n'elu.

2. Isi ihe na-akpata nke siri ike elu eyi na-eguzogide surfacing cracks

Enwere ọtụtụ ihe na-akpata mgbawa. N'ihi na ike n'elu eyi na-eguzogide surfacing ịgbado ọkụ, ọ nwere ike tumadi kewara n'ime ọkụ cracks nwere ike ịchọta mgbe mbụ ma ọ bụ nke abụọ ngafe, na oyi na-atụ cracks na-apụta mgbe nke abụọ ngafe ma ọ bụ ọbụna mgbe niile ịgbado ọkụ.

Mgbawa na-ekpo ọkụ:

N'oge usoro ịgbado ọkụ, metal dị na weld seam na okpomọkụ na-emetụta mpaghara oyi na-ekpo ọkụ na mpaghara okpomọkụ dị nso na eriri siri ike iji mepụta mgbawa.

Oyi mgbawa:

Ihe mgbawa na-eme na okpomọkụ dị n'okpuru ebe siri ike (ihe dị ka na mgbanwe mgbanwe martensitic nke ígwè) na-emekarị na nchara carbon-carbon na ike dị elu na-adị ala na ihe ndị na-emepụta ihe.

Dị ka aha ahụ na-egosi, a na-ama ngwaahịa ndị siri ike maka elu elu ha. Otú ọ dị, nchụso nke ike na-arụ ọrụ na-ebutekwa mbelata nke plasticity, ya bụ, mmụba nke nrịkasị ahụ. N'ikwu okwu n'ozuzu, ịwụ elu n'elu HRC60 anaghị etinye uche dị ukwuu na mgbawa ọkụ na-emepụta n'oge usoro ịgbado ọkụ. Otú ọ dị, ịgbado ọkụ siri ike nke siri ike n'etiti HRC40-60, ma ọ bụrụ na ọ dị mkpa maka mgbawa, The intergranular cracks na usoro ịgbado ọkụ ma ọ bụ liquefaction na multilateral cracks nke elu weld bead na-ekpo ọkụ na-emetụta mpaghara nke ala weld. bead na-enye nsogbu.

Ọbụna ma ọ bụrụ na a na-achịkwa nsogbu nke mgbawa ọkụ na-ekpo ọkụ nke ọma, egwu nke mgbawa oyi ka ga-eche ihu mgbe ịgbado ọkụ dị n'elu, karịsịa ihe ndị na-agbaji agbaji dị ka bead weld siri ike, bụ nke na-enwe mmetụta karịa mgbawa oyi. Ihe na-akpatakarị mgbawa siri ike bụ mgbawa oyi

3. Ihe ndị dị mkpa na-emetụta ihe ndị na-adịghị mma na-eyi n'elu ebe siri ike na atụmatụ iji zere mgbawa

Ihe ndị dị mkpa a ga-enyocha mgbe mgbawa na-eme na usoro iyi akwa siri ike bụ ndị a, a na-atụkwa atụmatụ dabara adaba maka ihe ọ bụla iji belata ihe ize ndụ nke mgbawa:

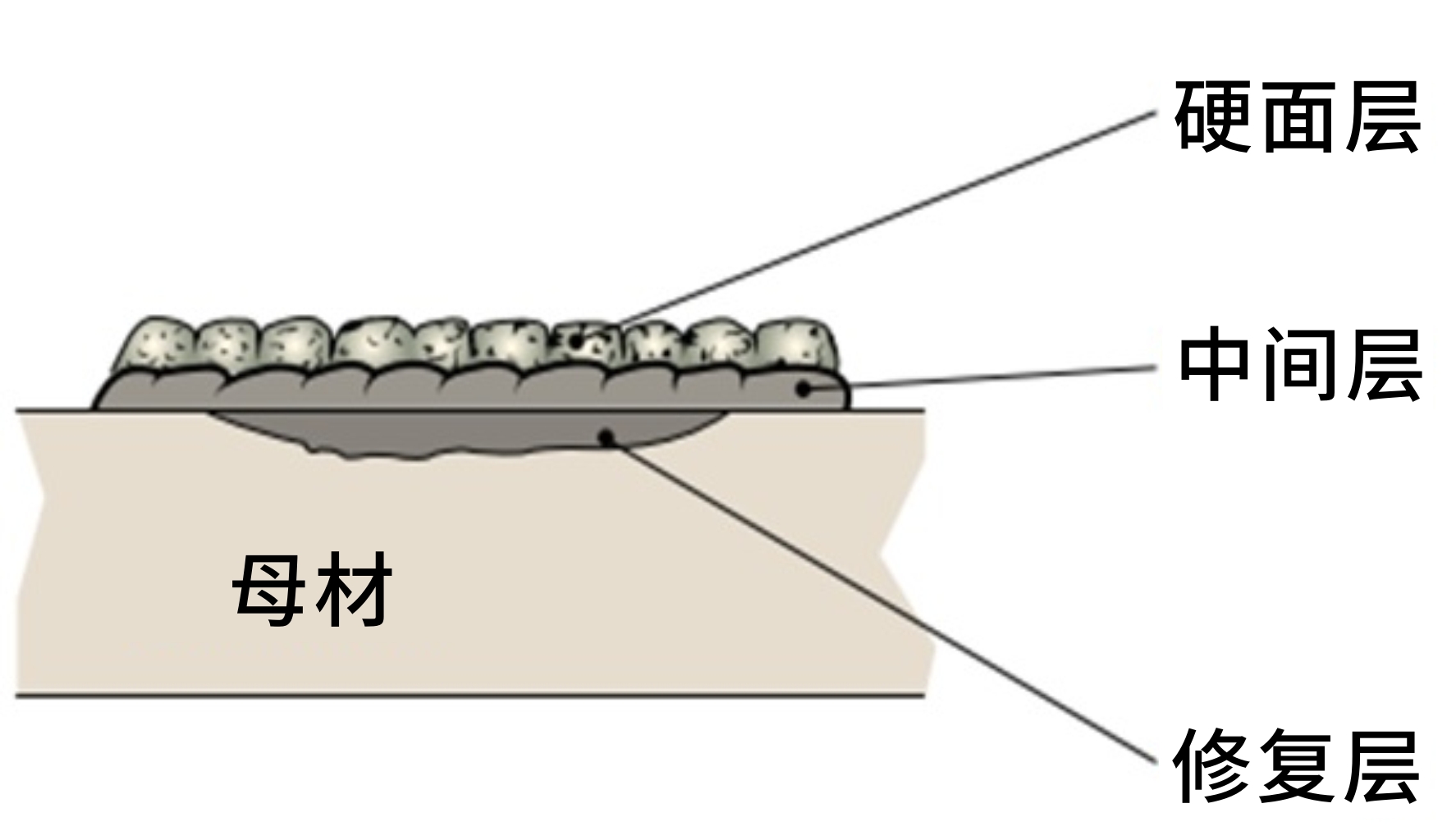

1. Ihe ndabere

Mmetụta nke isi metal na ike elu eyi na-eguzogide surfacing dị ezigbo mkpa, karịsịa maka workpieces na-erughị 2 n'ígwé nke surfacing ịgbado ọkụ. Ngwakọta nke metal ntọala na-emetụta kpọmkwem njirimara nke bead weld. Nhọrọ ihe eji eme ihe bụ nkọwa dị mkpa ka elele anya tupu ịmalite ọrụ. Dịka ọmụmaatụ, ọ bụrụ na valvụ workpiece nwere ihe siri ike nke ihe dị ka HRC30 na-eji ihe ntọala nkedo na-ejupụta, a na-atụ aro ka iji ihe ịgbado ọkụ nwere obere isi ike dị ala, ma ọ bụ gbakwunye oyi akwa nke igwe anaghị agba nchara n'etiti. zere ọdịnaya carbon dị n'ime ihe ndabere ka ọ ghara ịbawanye ohere nke mgbawa bead weld.

Tinye ihe nkedo etiti na ihe ndabere iji belata ihe ize ndụ nke mgbawa

2. Welding consumables

Maka usoro nke na-achọghị mgbawa, nnukwu carbon na chromium welding consumable adịghị adabara. A na-atụ aro ka iji usoro ịgbado ọkụ nke martensitic, dị ka GFH-58 anyị. Ọ nwere ike ịgbanye elu bead na-enweghị mgbape mgbe ike siri ike dị elu dị ka HRC58 ~ 60, nke dabara adaba maka ebe arụ ọrụ na-abụghị nke atụmatụ nke na-emebi ala na nkume.

3. Ntinye ọkụ

Owuwu na saịtị na-achọsi ike iji elu ugbu a na voltaji n'ihi na-emesi ike na arụmọrụ, ma moderately ibelata ugbu a na voltaji nwekwara ike n'ụzọ dị irè ibelata omume nke thermal cracks.

4. Njikwa okpomọkụ

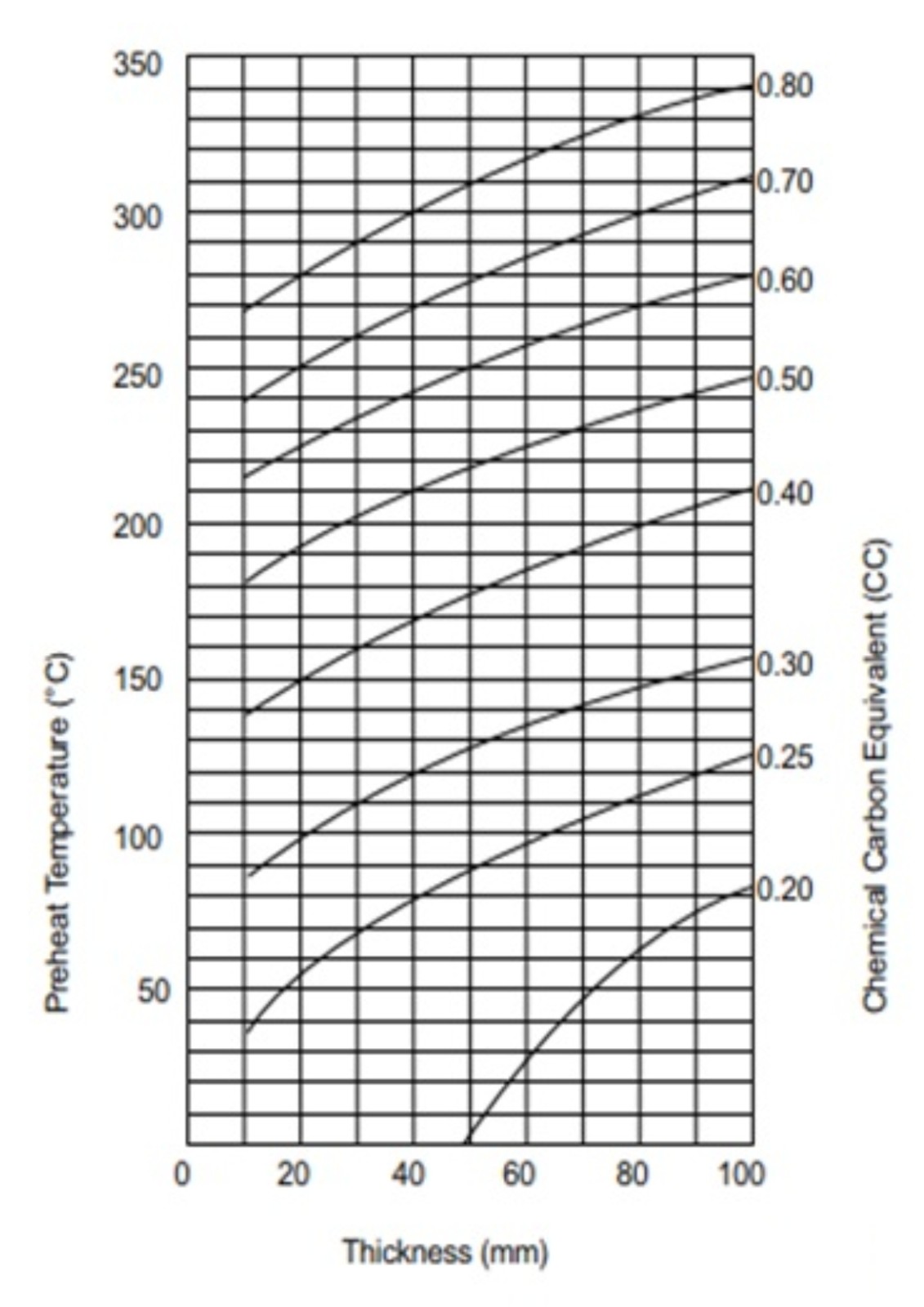

Multi-layer na multi-pass hardfacing ịgbado ọkụ nwere ike na-ahuta dị ka a usoro nke na-aga n'ihu kpo oku, jụrụ na reheating maka onye ọ bụla ngafe, otú okpomọkụ akara dị ezigbo mkpa, si preheating tupu ịgbado ọkụ na-agafe okpomọkụ n'oge surfacing Control, na ọbụna jụrụ usoro mgbe. ịgbado ọkụ, chọrọ oké anya.

Igwe ọkụ na-ekpo ọkụ na egwu egwu nke ịgbado ọkụ dị n'elu nwere njikọ chiri anya na ọdịnaya carbon nke mkpụrụ. Mkpụrụ ebe a na-agụnye ihe ndabere ma ọ bụ oyi akwa etiti, na ala nke elu ahụ siri ike. N'ikwu okwu n'ozuzu, n'ihi ọdịnaya carbon nke elu siri ike nke a na-edebe metal Ọ bụrụ na ọdịnaya dị elu, a na-atụ aro ka ị nọgide na-enwe okpomọkụ n'okporo ụzọ karịa 200 degrees. Otú ọ dị, n'ime ọrụ n'ezie, n'ihi ogologo ogologo nke weld bead, akụkụ ihu nke weld bead ejiriwo njedebe nke otu ngafe mee ka ọ dị jụụ, na nke abụọ ga-eme ka ọ dị mfe na-emepụta mgbape na mpaghara okpomọkụ emetụtara nke mkpụrụ. . Ya mere, na enweghị akụrụngwa kwesịrị ekwesị iji nọgide na-enwe okpomọkụ ọwa ma ọ bụ preheat tupu ịgbado ọkụ, a na-atụ aro ka ị rụọ ọrụ n'ọtụtụ akụkụ, obere welds, na ịgbado ọkụ na-aga n'ihu n'otu akụkụ iji nọgide na-enwe okpomọkụ nke ọwa.

Mmekọrịta dị n'etiti ọdịnaya carbon na ikpo ọkụ ọkụ

Ịdị jụụ ngwa ngwa mgbe ịsafesa ahụ gasịrị bụkwa usoro dị oke egwu mana a na-elegharakarị anya, karịsịa maka nnukwu workpieces. Mgbe ụfọdụ ọ naghị adị mfe ịnweta akụrụngwa kwesịrị ekwesị iji nye ọnọdụ jụrụ oyi nwayọ. Ọ bụrụ na ọ dịghị ụzọ ọ bụla iji dozie ọnọdụ a, anyị nwere ike ịkwado iji ya ọzọ Usoro nke ọrụ nkebi, ma ọ bụ zere ịgbado ọkụ n'elu mgbe okpomọkụ dị ala, iji belata ihe ize ndụ nke mgbawa oyi.

Anọ. Mmechi

A ka nwere ọtụtụ ndị na-emepụta ihe dị iche na ihe ndị chọrọ hardfacing maka cracks na ngwa bara uru. Edemede a na-eme naanị mkparịta ụka siri ike dabere na ahụmịhe nwere oke. Ụlọ ọrụ anyị siri ike n'elu eyi-eguzogide usoro nke ịgbado ọkụ consumables nwere kwekọrọ ekwekọ ngwaahịa maka ndị ahịa ịhọrọ dị iche iche hardness na ngwa. Nabata ka ị kparịta ụka na azụmahịa na mpaghara ọ bụla.

Ngwa nke ụlọ mmepụta ihe mejupụtara osisi na-eguzogide eyi

| Ihe | Chebe gas | nha | Isi | HRC | Iji |

| GFH-61-0 | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Si: 0.6 Mn:1.2 C: 28.0 | 61 | Kwesịrị ekwesị maka igwe egweri, igwe igwe simenti, bulldozers, wdg. |

| GFH-65-0 | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Mkp: 22.5 Mo: 3.2 V: 1.1 W: 1.3 Nb:3.5 | 65 | Kwesịrị ekwesị maka oke okpomọkụ na-ewepu uzuzu fan agụba, ihe mgbawa ọkụ ọkụ, wdg. |

| GFH-70-O | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Kr: 30.0 B:0.3 | 68 | Ọdabara na rola coal, mmụọ na-acha ọbara ọbara, ngwa nnata, mkpuchi coal, grinder, wdg. |

Ngwa na ụlọ ọrụ ciment

| Ihe | Chebe gas | nha | Isi | HRC | Iji |

| GFH-61-0 | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Si: 0.6 Mn:1.2 C: 28.0 | 61 | Kwesịrị ekwesị maka egweri rollers nkume, ndị na-agwakọta ciment, wdg |

| GFH-65-0 | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Mkp: 22.5 Mo: 3.2 V: 1.1 W: 1.3 Nb:3.5 | 65 | Kwesịrị ekwesị maka oke okpomọkụ na-ewepu uzuzu fan agụba, ihe mgbawa ọkụ ọkụ, wdg. |

| GFH-70-O | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Kr: 30.0 B:0.3 | 68 | Kwesịrị ekwesị maka ịkwanye rollers nkume, ezé mmụọ, ịnata ezé, grinders, wdg. |

| GFH-31-S | GXH-81 | 2.8 3.2 | C: 0.12 Aha: 0.87 Ọnụ:2.6 Mo: 0.53 | 36 | Ọdabara na metal-to-metal wear akụkụ dị ka okpueze wiil na axles |

| GFH-17-S | GXH-81 | 2.8 3.2 | C: 0.09 Aha: 0.42 Mn:2.1 Kr: 2.8 Mo: 0.43 | 38 | Ọdabara na metal-to-metal wear akụkụ dị ka okpueze wiil na axles |

Ngwa osisi ígwè

| Ihe | Chebe gas | nha | Isi | HRC | Iji |

| GFH-61-0 | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Si: 0.6 Mn:1.2 C: 28.0 | 61 | Kwesịrị ekwesị maka ịgbanye ogwe ọkụ ọkụ osisi, ezé mmụọ, efere ndị na-adịghị eyi uwe, wdg. |

| GFH-65-0 | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Mkp: 22.5 Mo: 3.2 V: 1.1 W: 1.368 Nb:3.5 | 65 | |

| GFH-70-0 | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Kr: 30.0 B:0.3 | 68 | |

| GFH-420-S | GXH-81 | 2.8 3.2 | C: 0.24 Aha: 0.65 Mn:1.1 Mkp: 13.2 | 52 | Kwesịrị ekwesị maka nkedo mpịakọta, ibufe mpịakọta, mpịakọta steering, wdg. na osisi nkedo na-aga n'ihu na osisi na-ekpo ọkụ na-agbagharị. |

| GFH-423-S | GXH-82 | 2.8 3.2 | C: 0.12 Aha: 0.42 Mn:1.1 Mkp: 13.4 Mo: 1.1 V: 0.16 Nb:0.15 | 45 | |

| GFH-12-S | GXH-81 | 2.8 3.2 | C: 0.25 Aha: 0.45 Nn:2.0 Kr: 5.8 Mo: 0.8 V: 0.3 W:0.6 | 51 | Ihe eji eme ihe na-egbochi ntanye, dabara adaba maka mpịakọta ụlọ ọrụ efere igwe, tuo mpịakọta na eyi akụkụ n'etiti ọla. |

| GFH-52-S | GXH-81 | 2.8 3.2 | C: 0.36 Aha: 0.64 Nn:2.0 Nke: 2.9 Kr: 6.2 Mo: 1.35 V: 0.49 | 52 |

Ngwa Miner

| Ihe | Chebe gas | nha | Isi | HRC | Iji |

| GFH-61-0 | Nchekwa onwe | 1.6 2.8 3.2 | C: 5.0 Si: 0.6 Mn:1.2 C: 28.0 | 61 | Ọdabara maka ndị na-egwupụta ihe, ndị isi okporo ụzọ, nhọpụta, wdg. |

| GFH-58 | CO2 | 1.6 2.4 | C: 0.5 Si: 0.5 Nkeji: 0.95 Nọmba: 0.03 Kr: 5.8 Mo: 0.6 | 58 | Kwesịrị ekwesị maka ịgbado ọkụ surfacing n'akụkụ nkume nnyefe trough |

| GFH-45 | CO2 | 1.6 2.4 | C: 2.2 Si: 1.7 Nn:0.9 Mkp: 11.0 Mo: 0.46 | 46 | Kwesịrị ekwesị maka iyi akụkụ n'etiti ọla |

Ngwa Valve

| Ihe | Chebe gas | nha | Isi | HRC | Iji |

| GFH-D507 | CO2 | 1.6 2.4 | C: 0.12 S: 0.45 Nn:0.4 Nke: 0.1 Mkp:13 Mo: 0.01 | 40 | Kwesịrị ekwesị maka ịgbado ọkụ nke elu valve akara |

| GFH-D507Mo | CO2 | 1.6 2.4 | C: 0.12 S: 0.45 Nn:0.4 Nke: 0.1 Mkp:13 Mo: 0.01 | 58 | Kwesịrị ekwesị maka ịgbado ọkụ nke valves na nnukwu corrosiveness |

| GFH-D547Mo | mkpanaka aka | 2.6 3.2 4.0 5.0 | C: 0.05 Ọnụ:1.4 Nkeji: 5.2 P:0.027 S: 0.007 Nke: 8.1 C: 16.1 Mo: 3.8 Nb:0.61 | 46 | Kwesịrị ekwesị maka okpomọkụ dị elu, akwa valve surfacing welding |

More information send to E-mail: export@welding-honest.com

Oge nzipu: Dec-26-2022