I. Nchịkọta

Site na mmepe ngwa ngwa nke mmepụta ụlọ ọrụ igwe, ihe owuwu welded dị ka injinia ọgbara ọhụrụ na ụgbọ mmiri nrụgide na-etolite n'ụzọ na-abawanyewanye ibu ma dị fechaa. Ihe ndị a chọrọ maka akara ike ígwè na-adị elu ma dị elu, ọ bụghị nanị na-achọ ihe ndị dị mma n'ibu, kamakwa ezi usoro nhazi, weldability na mgbape na-eguzogide.

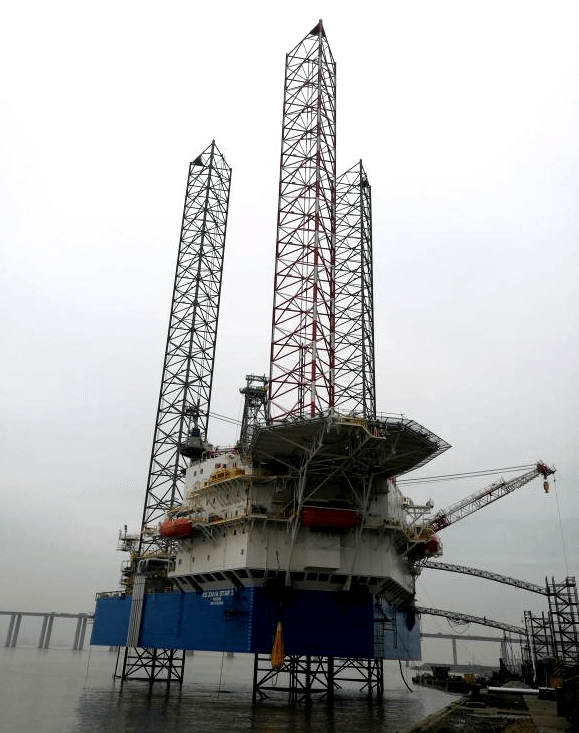

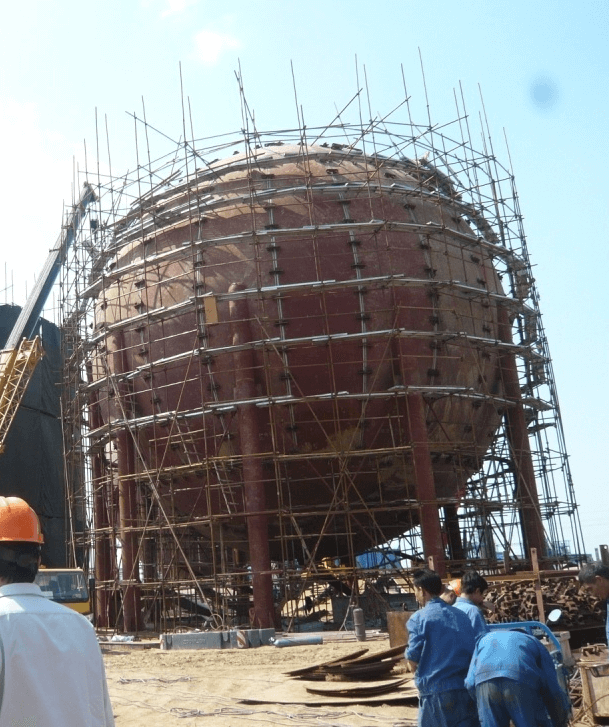

Q690 ígwè bụ nke elu-ike welded structural ígwè, ebe Q na-anọchi anya mkpụrụ, na 690 pụtara na mkpụrụ ike larịị bụ 690MPa. 690MPa ọkwa ígwè nwere nnukwu mkpụrụ na ike tensile, ma na-ejikarị na coal Ngwuputa ígwè, ihe owuwu ígwè, mmiri engineering, offshore nyiwe, nrụgide arịa, wdg, na-achọ ígwè inwe elu mkpụrụ ike na ike ọgwụgwụ, ezigbo mmetụta siri ike, oyi oyi. formability na ezigbo weldability.

2.Brief iwebata nke Q690 ígwè efere

| Mba ụwa Q690 ígwè ọkwa | Q690A | Q690B | Q690C | Q690D | Q690E | Q690F |

| Nku | Hot akpọrepu | Quenching + iwe (emenyụ na ọnọdụ iwe) | ||||

| Ọdịnaya adịghị ọcha | P/S dị elu | obere P/S | P/S kacha nta | |||

| Ihe ịma jijiji chọrọ | NO | Nkịtị okpomọkụ ujo | 0℃ | -20 ℃ | -40 ℃ | -60 ℃ |

Otú ọ dị, ugbu a, efere ígwè 690MPa maka ụgbọ mmiri nrụgide ụlọ na-adabere na ọkọlọtọ European EN10028-6, ma e depụtara ihe ndị dị mkpa na tebụl na-esonụ:

| Mpụta 690MPA ígwè maka akụrụngwa nrụgide ọkọlọtọ Europe | P690Q | P690QH | P69QL1 | P69QL2 |

| Nku | ezigbo ọka emenyu na ígwè dị ọkụ | |||

| ike chọrọ | Mpụta≥690MPa(efere ọkpụrụkpụ≤50mm) Tensile770-940MPa | |||

| Ọdịnaya adịghị ọcha | P≤0.025%, S≤0.015% | P≤0.02%, S≤0.010% | ||

| Ihe ịma jijiji chọrọ | 20℃≥60J | 20℃≥60J | 0℃≥60J | -20℃≥40J |

| 0℃≥40J | 0℃≥40J | -20℃≥40J | -40℃≥27J | |

| -20℃≥27J | -20℃≥27J | -40℃≥27J | -60℃≥27J | |

| Mpaghara ngwa ngwa | Akụkụ na-ebu nrụgide ma ọ bụ arịa nrụgide nwere mmetụta siri ike dị ala chọrọ | Spherical tank na elu oru chọrọ | Mmiri mmiri mmiri na-ekpo ọkụ gas | |

Dị ka efere ígwè maka tankị nchekwa na ikike nrụgide, ọ ghaghị inwe ike dị mma na ike siri ike, arụmọrụ na-ehulata oyi na obere mgbagwoju anya. Ọ bụ ezie na nchara Q690 na-ekpo ọkụ ma na-ekpo ọkụ nwere obere carbon nke dabara na ọmarịcha ihe zuru oke, ọ ka nwere àgwà siri ike ma e jiri ya tụnyere ndị ọzọ 50/60kg mgbali arịa steels, na post-weld ọgwụgwọ a chọrọ. Otú ọ dị, ọnụ ọgụgụ dị ukwuu nke nnyocha ọmụmụ egosiwo na maka Q690 ígwè ịgbado ọkụ consumables, na ala-okpomọkụ mmetụta siri ike ga-abụ nke ukwuu njọ mgbe nchekasị enyemaka okpomọkụ ọgwụgwọ, na na-abawanye nke okpomọkụ ọgwụgwọ okpomọkụ na mbelata nke mmetụta okpomọkụ, na-emebi emebi. nke ịgbado ọkụ consumable siri ike ga-abụ ihe doro anya. Ya mere, ọ bụ ihe bara uru dị ukwuu ịzụlite ike dị elu, mmetụta siri ike, na ikpo ọkụ na-ekpo ọkụ maka Q690 ígwè iji mee nke ọma n'itinye Q690 ígwè na ngwá ọrụ nrụgide, belata ihe nchara, ma belata ụgwọ ọrụ mmepụta ihe.

3.Brief iwebata nke anyị Q690 ígwè ịgbado ọkụ mkpanaka

| Ihe | Ọkọlọtọ | Ụdị akpụkpọ ahụ | Polarity | isi atụmatụ |

| GEL-118M | AWS A5.5 E1108MISO 18275-BE7618-N4M2A | Iron ntụ ntụ obere hydrogen ụdị | DC+/AC | Ike dị elu, hydrogen dị ala, arụmọrụ dị elu, akụrụngwa akụrụngwa kwụsiri ike, mmetụta siri ike dị ala dị ala na -50 Celsius, yana mmetụta siri ike na -40 Celsius C mgbe ọgwụgwọ okpomọkụ gasịrị. |

| GEL-758 | AWS A5.5 E11018-GISO 18275-BE7618-G A | Iron ntụ ntụ obere hydrogen ụdị | DC+/AC | Ultra-ala hydrogen, elu ntinye arụmọrụ, elu siri ike (-60 ℃≥70J), mmetụta siri ike na -40/-50 ℃ mgbe ọgwụgwọ okpomọkụ gasịrị. |

| GEL-756 | AWS A5.5 E11016-GISO 18275-BE7616-G A | Ụdị potassium hydrogen dị ala | AC/DC+ | Ultra-ala hydrogen, AC / DC + dual-nzube, elu mmetụta siri ike (-60 ℃≥70J), mmetụta dị mma siri ike na -50 / -60 ℃ mgbe ọgwụgwọ okpomọkụ gasịrị. |

4.Q690 ígwè ịgbado ọkụ mkpanaka n'ibu arụmọrụ ngosi

| Ihe | Dị ka-welded n'ibu Njirimara | ||||||

| Mpụta MPA | MPA nkwụsi ike | Gbatịa % | Mmetụta ihe onwunwe J/℃ | Nnwale redio | hydrogen nwere ike ịgbasa ml/100g | ||

| -50 ℃ | -60 ℃ | ||||||

| AWS A5.5 E11018M | 680- 760 | ≥760 | ≥20 | ≥27 | - | I | - |

| ISO 18275-B E7618-N4M2A | 680- 760 | ≥760 | ≥18 | ≥27 | - | I | - |

| GEL-118M | 750 | 830 | 21.5 | 67 | 53 | I | 3.2 |

| AWS A5.5 E1101X-G | ≥670 | ≥760 | ≥15 | - | - | I | - |

| ISO 18275B E761X-GA | ≥670 | ≥760 | ≥13 | - | - | I | - |

| GEL-758 | 751 | 817 | 19.0 | 90 | 77 | I | 3.4 |

| GEL-756 | 764 | 822 | 19.0 | 95 | 85 | I | 3.6 |

Kọwaa:

1. The "X" akara na-acha uhie uhie font na American Standard na European Standard na-anọchite anya ụdị akpụkpọ ọgwụ.

2. GEL-758 kwekọrọ na E11018-G na ISO 18275-B E7618-G A na ụkpụrụ AWS na ISO n'otu n'otu.

3. GEL-756 kwekọrọ na E11016-G na ISO 18275-B E7616-G A na ụkpụrụ AWS na ISO n'otu n'otu.

Mechanical Njirimara nke Q690 ígwè ịgbado ọkụ mkpanaka na okpomọkụ ọgwụgwọ steeti

| Ihe | Mechanical Njirimara nke okpomọkụ mesoo ala | ||||||

| Mpụta MPA | MPA nkwụsi ike | Gbatịa % | Mmetụta ihe onwunwe J/℃ | kpo oku ℃*h | |||

| -40 ℃ | -50 ℃ | -60 ℃ | |||||

| Ebumnuche oru ngo | ≥670 | ≥760 | ≥15 | ≥60 | ≥52 | ≥47 | 570*2 |

| GEL-118M | 751 | 827 | 22.0 | 85 | 57 | - | 570*2 |

| GEL-758 | 741 | 839 | 20.0 | 82 | 66 | 43 | 570*2 |

| GEL-756 | 743 | 811 | 21.5 | 91 | 84 | 75 | 570*2 |

Kọwaa:

1. AWS na ụkpụrụ ISO metụtara enweghị ọrụ ọgwụgwọ okpomọkụ chọrọ maka ngwaahịa ndị dị n'elu. A na-achịkọta ọgwụgwọ okpomọkụ dị n'elu dabere na ọnọdụ teknụzụ nke ọtụtụ ndị ahịa ma bụrụ maka ntụaka naanị.

2. GEL-118M nwere mmetụta siri ike dị mma na -40 ° C mgbe ọgwụgwọ okpomọkụ gasịrị, na mmetụta mmebi na -50 ° C bụ ihe doro anya.

3. Mgbe ọgwụgwọ okpomọkụ gasịrị, GEL-758 nwere mmetụta siri ike dị mma na -40 ° C, mmetụta siri ike na -50 ° C, na mmebi doro anya na obere okpomọkụ na -60 ° C.

4. Mmetụta dị ala na-emetụta ike ike nke GEL-756 mgbe ọgwụgwọ okpomọkụ dị ntakịrị, na obere okpomọkụ siri ike na -60 ° C ka dị mma.

Weldability ngosi nke Q690 ígwè ịgbado ọkụ mkpanaka

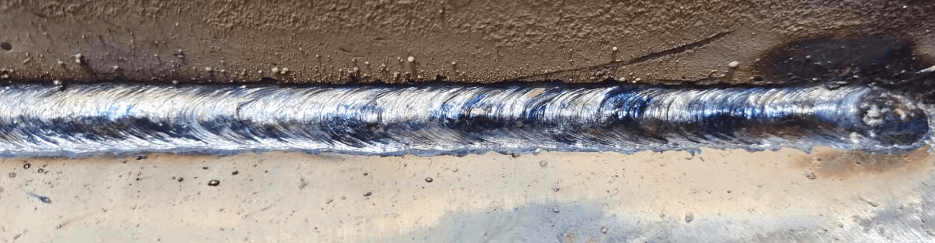

1.Flat fillet ịgbado ọkụ (φ4.0mm)

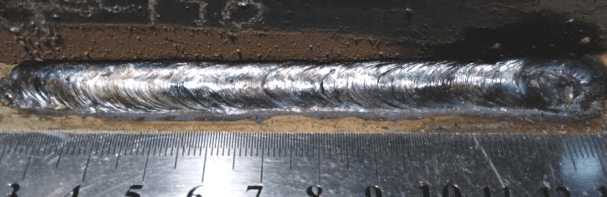

GEL-118M flat fillet ịgbado ọkụ tupu na mgbe slag mwepụ (DC+)

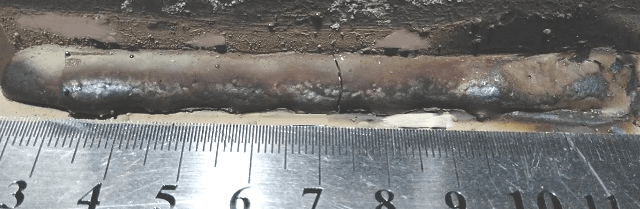

Tupu na mgbe GEL-758 flat fillet ịgbado ọkụ slag mwepụ (DC+)

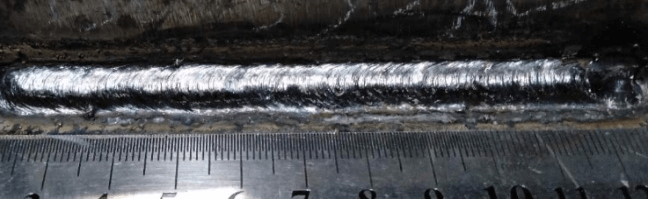

GEL-756 flat fillet ịgbado ọkụ tupu na mgbe slag mwepụ (AC)

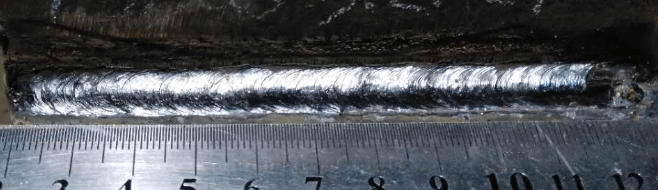

GEL-756 flat fillet ịgbado ọkụ tupu na mgbe slag mwepụ (DC+))

Q690 ígwè ịgbado ọkụ mkpanaka mkpara ịgbado ọkụ

1. Nchekwa ihe eji agbado ọkụ:

A na-atụ aro ka a na-echekwa ihe eji agbado ọkụ n'okpuru okpomọkụ na ọnọdụ akọrọ mgbe niile, ma tinye ya na pallets ma ọ bụ shelves, na-ezere kọntaktị kpọmkwem na mgbidi na ala.

2. Nkwadebe tupu ịgbado ọkụ:

Wepụ nke ọma mmiri mmiri, nchara, ntụpọ mmanụ, wdg n'elu ihe dị n'okpuru, ma zere mmiri mmiri ma ọ bụ ikpughe na mmiri ozuzo na snow.

3. Ihe mgbochi ikuku:

Mgbe ị na-agbado ọkụ, ekwesịrị ijide n'aka na ikuku kachasị na ebe ịgbado ọkụ adịghị agafe 2m / s. Ma ọ bụghị ya, ekwesịrị ịme usoro nchebe.

4. Ịkpọ ọkụ:

A na-atụ aro ka iji ngwa kpo oku ọkụ eletrik mee ka ọrụ ahụ dị elu karịa 150 ° C tupu ịgbado ọkụ. Ọbụlagodi tupu ịgbado ọkụ, a ga-ebu ụzọ kpoo ya n'elu 150 Celsius.

5. Njikwa oyi akwa na okporo ụzọ:

N'oge usoro ịgbado ọkụ niile, ikuku interpass ekwesịghị ịdị ala karịa okpomoku a na-ekpo ọkụ, yana okpomọkụ a na-atụ aro bụ 150-220 Celsius.

6. Mwepụ hydrogen mgbe ịgbado ọkụ:

Mgbe weld seam na-welded, ozugbo mee ka okpomọkụ nke ọkụ eletrik ruo 250 ℃ ~ 300 ℃, na-ekpo ọkụ maka awa 2 ruo 4, wee dị jụụ nwayọọ nwayọọ.

① Ọ bụrụ na ọkpụrụkpụ nke workpiece bụ ≥50mm, ejide oge kwesịrị ịgbatị ruo 4-6 awa, wee mma nwayọọ nwayọọ.

② N'okpuru ọnọdụ nke nnukwu ọkpụrụkpụ na nnukwu njide, enwere ike ịgbakwunye dehydrogenation ọzọ mgbe ịgbado ọkụ na 1/2 ọkpụrụkpụ, ma jiri nwayọọ nwayọọ mee ka okpomọkụ dị n'etiti.

7. Nhazi ala:

A na-atụ aro ka iji multi-layer na multi-pass welding, na ịgbado ọkụ kwesịrị ịdị na-agba ọsọ ọsọ.

More information send to E-mail: export@welding-honest.com

Oge nzipu: Jan-10-2023