I. Nchịkọta

Site na mmepe ngwa ngwa nke kemịkalụ kemịkalụ mba ụwa na akụrụngwa ume, a na-eji tankị igwe anaghị agba nchara na arịa dị iche iche na-ebugharị na nchekwa nke kemịkalụ, nri na ihe ọṅụṅụ, ike na ihe ndị ọzọ. N'ihi ịdị mma ya dị oke ala na nguzogide corrosion dị mma, a na-eji igwe anaghị agba nchara austenitic na-ewu tankị nchekwa, akụrụngwa na nnukwu ihe owuwu cryogenic.

Ebe nchekwa nke cryogenic

2.Brief iwebata nke anyị -196 ℃ obere okpomọkụ mmetụta igwe anaghị agba nchara ịgbado ọkụ consumables

| Otu | Aha | Nlereanya | Ọkọlọtọ | kwuo | |

| GB/YB | AWS | ||||

| Electrode | GES-308LT | A002 | E308L-16 | E308L-16 | -196℃≥31J |

| Flux waya | GFS-308LT | - | TS 308L-F C11 | E308LT1-1 | -196℃≥34J |

| waya siri ike | GTS-308LT (TIG) | - | H022Cr21Ni10 | ER308L | -196℃≥34J |

| GMS-308LT (MIG) | - | H022Cr21Ni10 | ER308L | -196℃≥34J | |

| SAW | GWS-308/ GXS-300 | - | S F308L FB-S308L | ER308L | -196℃≥34J |

3.Our electrode GES-308LT (E308L-16)

Iji gboo mkpa ahịa, ụlọ ọrụ anyị emepụtala ụdị okpomọkụ dị iche iche dị ala, ike siri ike austenitic igwe anaghị agba nchara, ihe mejupụtara kemịkalụ nke ọla edobere (dị ka egosiri na Tebụl 1) na akụrụngwa akụrụngwa kwụsiri ike (dị ka egosiri na tebụl). 2), na nwere magburu onwe niile-ọnọdụ ịgbado ọkụ usoro Performance, na magburu onwe ala okpomọkụ mmetụta siri ike, mmetụta nke ya ferrite ego na mmetụta uru (Table 3).

1.Chemical mejupụtara nke metal echekwabara

| E308L-16 | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | N | Fn |

| NB (%) | 0.04 | 0.5-2.5 | 1.0 | 0,030 | 0.020 | 9.0-12.0 | 18.0-21.0 | 0.75 | 0.75 | - | - |

| Ihe atụ1 | 0.022 | 1.57 | 0.62 | 0.015 | 0,006 | 10.25 | 19.23 | 0.020 | 0.027 | 0.046 | 6.5 |

| Ihe atụ2 | 0,037 | 2.15 | 0.46 | 0.018 | 0,005 | 10.44 | 19.19 | 0.013 | 0.025 | 0.45 | 3.8 |

| Ihe atụ3 | 0.032 | 1.37 | 0.49 | 0.017 | 0,007 | 11.79 | 18.66 | 0.021 | 0.027 | 0,048 | 0.6 |

Tebụl 1

2.Mechanical Njirimara nke metal echekwabara

| E308L-16 | Mmụba MPa | Ịkwụsị MPa | Ogologo oge % | -196℃ezighi ezi J/℃ | GB/T4334-2020 E Intergranular corrosion | Rnyocha adiographic | kwuo | |

| Otu uru | Nkezi uru | |||||||

| NB | - | 510 | 30 | - | - | - | I | - |

| Ihe atụ1 | 451 | 576 | 42 | 32/32/33 | 32.3 | tozuru oke | I | - |

| Ihe atụ2 | 436 | 563 | 44 | 39/41/39 | 39.7 | tozuru oke | I | - |

| Ihe atụ3 | 412 | 529 | 44.5 | 52/53/55 | 53.3 | tozuru oke | I | - |

Tebụl 2

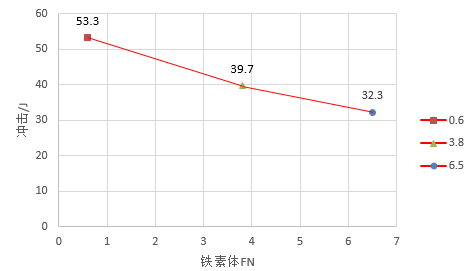

3. Mmetụta nke ego nkwụnye ego metal ferrite na mmetụta

4.Ngosipụta usoro ịgbado ọkụ (φ3.2mm)

Mgbado ọkụ kwụ ọtọ tupu na mgbe mwepụ slag (DC+)

Pipeline ịgbado ọkụ tupu na mgbe slag mwepụ (DC+)

4. Akpachara anya maka ịgbado ọkụ kwụ ọtọ

1. Ekwesịrị iji ịgbado ọkụ dị ala ugbu a;

2. Debe arc dị ka o kwere mee;

3. Mgbe arc na-agbanye n'akụkụ abụọ nke uzo ahụ, kwụsịtụ oge, na obosara swing na-achịkwa n'ime 3 ugboro dayameta nke electrode.

5.Pipeline foto nke ịgbado ọkụ consumables ngwa

N'ihi na -196 ℃ obere okpomọkụ mmetụta igwe anaghị agba nchara welding consumables, mgbe afọ nke nnyocha na mmepe nke ịgbado ọkụ consumables, anyị enweela kwekọrọ ekwekọ na-akwado ịgbado ọkụ consumables maka ịgbado ọkụ mkpara, siri ike cores, flux cores na submerged arcs, na mepụtara aka electrode na-aga n'ihu arcs. ịgbado ọkụ consumables maka niile-ọnọdụ ịgbado ọkụ , na nwere ọtụtụ engineering ngwa rụzuru, nabata ahịa ịkpọ na họrọ!

Oge nzipu: Dec-16-2022