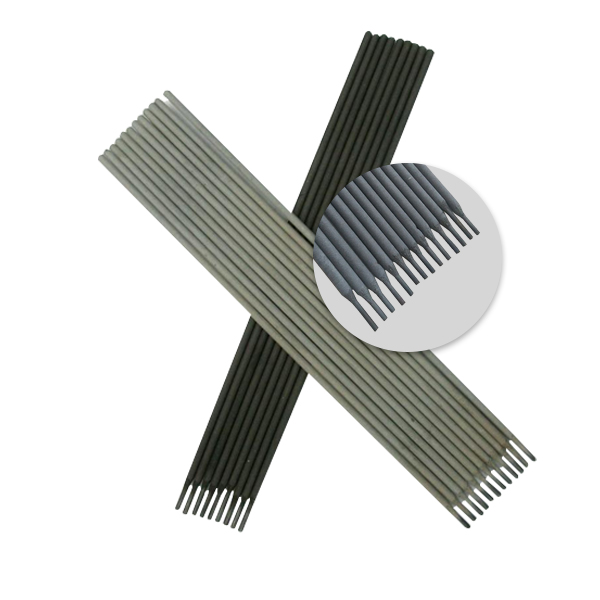

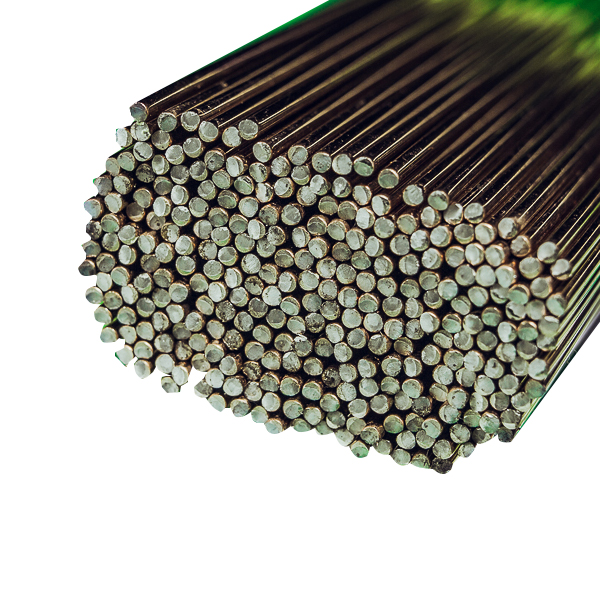

Carbon steels ntuziaka ntuziaka E9818-G na-ere ahịa

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T iwu | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| Iwu AWS | - | - | - | - | - | - | - | - | - | - |

| URU Ọmụmaatụ | 0,050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0,005 | 0,004 | 0.018 | 0,004 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | IMAPACT URU J/℃ | ELONGATION(%) | |||||

| GB/T iwu | - | - | - | - | - | |||||

| Iwu AWS | - | - | - | - | - | |||||

| URU Ọmụmaatụ | 915 | 992 | - | 65/-20 | 16 | |||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

980Mpa Super elu ike obere ferrohydrogen ntụ ntụ ụdị obere alloy ígwè electrode.

Arc kwụsiri ike, obere mkpọsa, mwepụ slag dị mma

Ọmarịcha arụmọrụ ịgbado ọkụ niile, ezigbo obere okpomọkụ siri ike, mgbape mgbape na mmetụta siri ike dị ala.

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T iwu | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| Iwu AWS | - | - | - | - | - | - | - | - | - | - |

| URU Ọmụmaatụ | 0,050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0,005 | 0,004 | 0.018 | 0,004 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | IMAPACT URU J/℃ | ELONGATION(%) | |||||

| GB/T iwu | - | - | - | - | - | |||||

| Iwu AWS | - | - | - | - | - | |||||

| URU Ọmụmaatụ | 915 | 992 | - | 65/-20 | 16 | |||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Dee ozi gị ebe a ziga anyị ya