Carbon steels ER70S-G data ịgbado ọkụ siri ike

Ngwa & Ọkọlọtọ

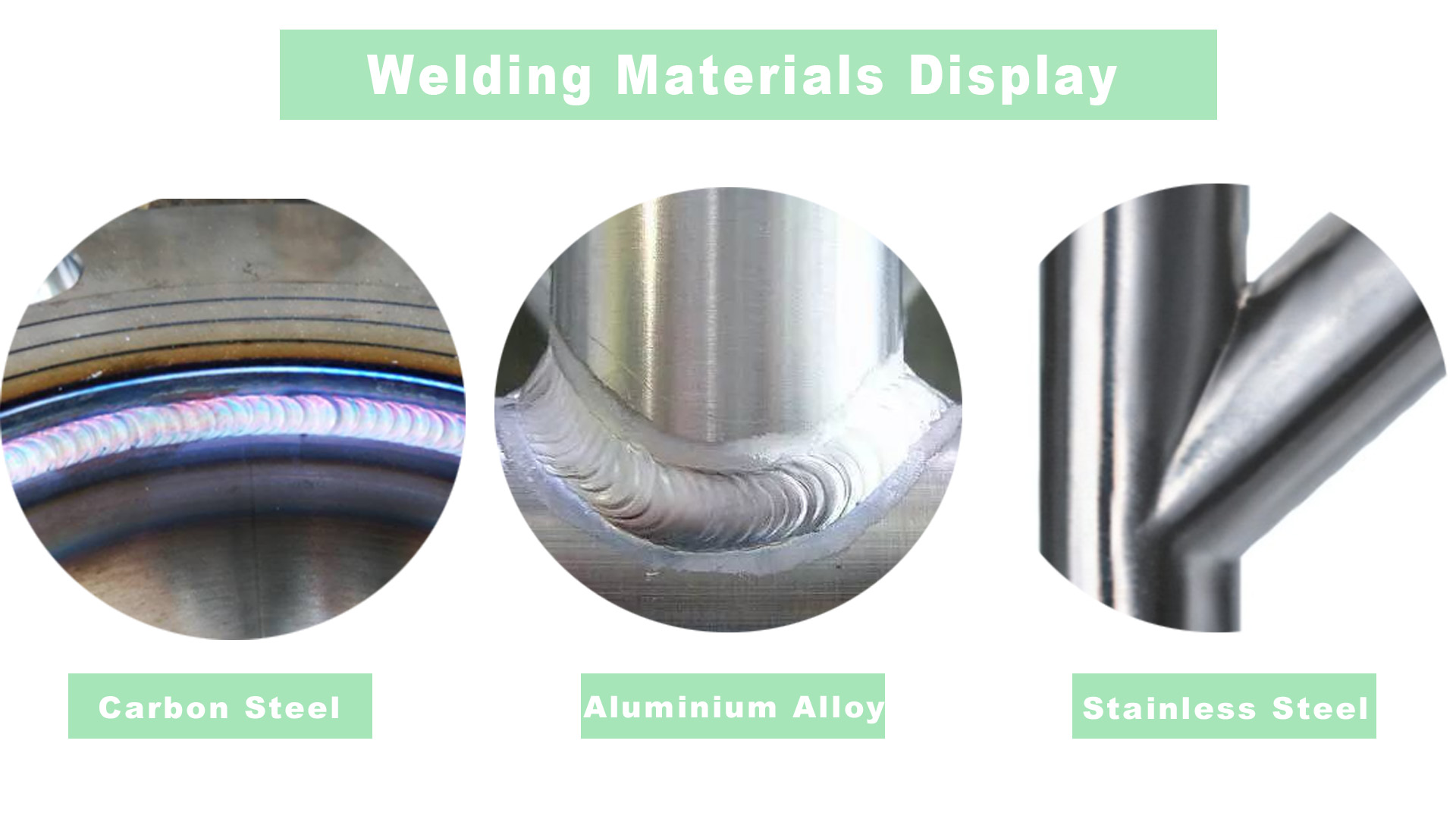

1. Kwesịrị ekwesị maka ịrụ ọrụ ụgbọ mmiri, akwa mmiri, ihe owuwu na ngwa ịgbado ọkụ, nke a na-ejikwa na mgbado ọkụ dị elu dị ugbu a na mkpịsị aka dị elu, ịgbado ọkụ fillet na ịgbado ọkụ cross.

2. Ọkọlọtọ anyị zutere: GB/T8110 G 49A4 C1/M21 S11 N , AWS A5.18 ER70S-G & A5.18M ER49S-G, ISO14341-A: G 42 4 C1/M21 Z4Si1, ISO 14341-B: G 49A 4 C1/M21 S11

JIS Z3312 YGW-11/15

Atụmatụ

1. Nchedo gburugburu ebe obibi na ahụike, ma nwee ike izere mmetụta ọjọọ nke ọla kọpa na àgwà ịgbado ọkụ;

2. Na mgbakwunye na ihe ndị kwesịrị ekwesị alloying dị ka Si na Mn, a na-agbakwunye ihe ndị Ti zuru ezu iji mee ka arc ahụ guzosie ike ma mee ka ntụgharị arc nụchaa; A na-ebelatakwa oke nrịbama na anwụrụ ọkụ;

3.Ti nwere ọrụ nke nchacha ọka nke weld pass, nke mere na ike nke weld ngafe na-mma nke ukwuu, na ọ nwekwara ike na-egwu ya elu arụmọrụ na nnukwu eruba ịgbado ọkụ.

Ụlọ ọrụ & Ụlọ ọrụ

NDỊ NA-ECHICHE

Asambodo

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Ti+Zr | P | S | Cu |

| GB/T iwu | 0.02-0.151 | 0.40-1.90 | 0.55-1.10 | - | - | - | 0.02-0.30 | 0,300 | 0,030 | 0,50 |

| Iwu AWS | - | - | - | - | - | - | - | - | - | - |

| URU Ọmụmaatụ | 0,055 | 1.500 | 0.85 | 0.03 | 0.02 | 0.01 | 0.18 | 0.013 | 0.010 | 0.02 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | IMAPACT URU J/℃ | ELONGATION(%) | |||||

| GB/T iwu | 390 | 490-670 | AW | 27/-40 | 18 | |||||

| Iwu AWS | 400 | 490 | AW | - | 22 | |||||

| URU Ọmụmaatụ | 500 | 590 | AW | 78/-40 | 28 | |||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 1 | 1.2 | 1.6 | |||||

| ELECTRICITY (Amp) | H/W | 80-250 | 100-350 | 250-300 | ||||

| O/W | 70-120 | 80-150 | - | |||||

IHE:

H/W: ịgbado ọkụ kwụ ọtọ. O/W: ịgbado ọkụ n'elu-isi

Ikike Asambodo: ABS/BV/CCS/DNV/GL/LR/NK/KR/RINA/CWB/RS/CE/VD/JIS