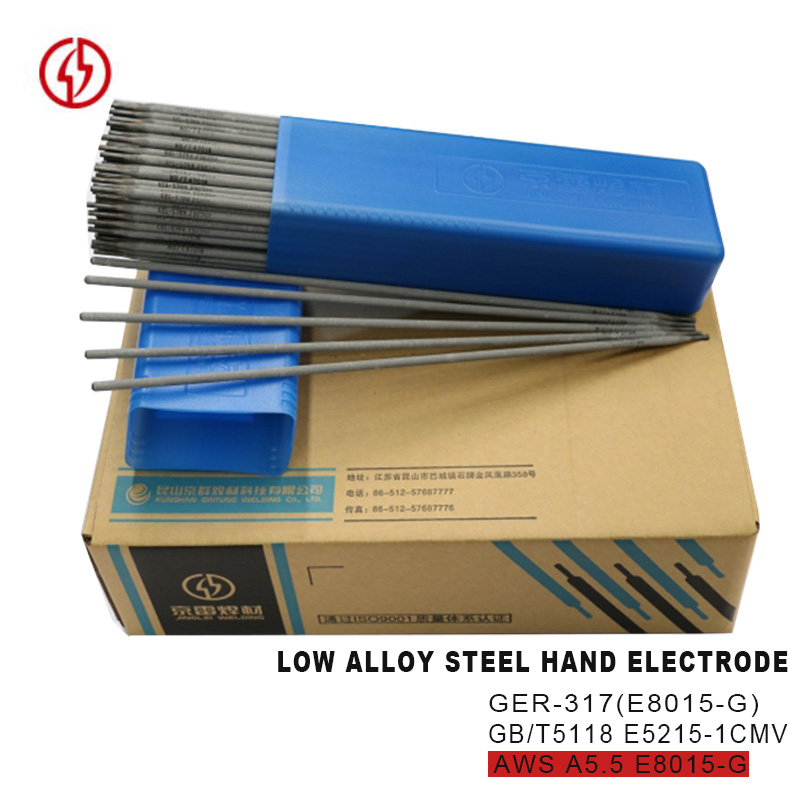

AWS E8015-G steel Alloy dị ala Ngwa ịgbado ọkụ siri ike

Ngwa&Ọkọlọtọ&Ndeeba:

AWS E8015-G ụdị aka ịgbado ọkụ electrode maka okpomọkụ na-eguzogide ígwè bụ adabara elu okpomọkụ na elu mgbali ọkụ pipeline nke ike ọdụ, elu okpomọkụ sịntetik chemical igwe, mmanụ ụgbọala refining ngwá, wdg na-arụ ọrụ okpomọkụ n'okpuru 540 ℃, dị ka 12CrMoV. Na nwekwara ike-eji na ịgbado ọkụ na-arụ ọrụ okpomọkụ n'okpuru 540 ℃, dị ka 15CrMo pearlite okpomọkụ na-eguzogide ọgwụ ígwè. Enwere ike iji ya wee weda igwe nkedo 30CrMnSi. Ọtụtụ n'ime ngwa ịgbado ọkụ nwere obere carbon ọdịnaya chọrọ nwere ike tinye na anyị okpomọkụ na-eguzogide ígwè electrode. Ọ na-ewu ewu nke ukwuu n'ahịa, yana nsonaazụ nzaghachi ahịa dịkwa mma nke ukwuu. Anyị na-anakwere teknụzụ mmepụta dị elu, na-achịkwa nke ọma inye akụrụngwa, nhazi na mmepụta ihe, nyocha ngwaahịa, ọrụ ahịa mgbe ọ bụla zuru ezu, iji nye ndị ahịa ihe kacha mma electrode na waya ọrụ.

Atụmatụ

AWS E8015-G ụdị ịgbado ọkụ electrode maka okpomọkụ na-eguzogide ígwè bụ obere sodium hydrogen ụdị aka ịgbado ọkụ electrode, na kwụsiri ike arc, obere splash, ezi ịkpụzi, mfe desagging, magburu onwe X-Ray arụmọrụ, kwụsiri ike n'ibu Njirimara, nwere ike ịnọgide na-enwe mmetụta siri ike siri ike. n'okpuru ọnọdụ ọgwụgwọ okpomọkụ. Nke a aka electrode bụ a pearlite okpomọkụ na-eguzogide ígwè electrode nwere 0,5% molybdenum, 1% chromium, vanadium, ojiji nke DC agbara ịgbado ọkụ ọrụ, nwere ike ịbụ niile ọnọdụ ịgbado ọkụ, mkpa preheat ka 250 ~ 300 ℃ tupu ịgbado ọkụ. Post-welding okpomọkụ ọgwụgwọ kwesịrị rụrụ na 730 ± 15 ℃ * 2h dị ka ọkọlọtọ chọrọ nke ịgbado ọkụ ihe. Na tupu ịgbado ọkụ, ọ dị mkpa iji wepụ mmanụ, nchara, mmiri na ọrụ ndị ọzọ na weldment.

Ụlọ ọrụ & Ụlọ ọrụ

Ngwaahịa mejupụtara na nrụnye Njirimara iwebata

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S | V |

| GB/T iwu | 0.05-0.12 | 0.90 | 0.60 | 0.80-1.50 | 0.40-0.65 | 0.03 | 0,030 | 0.10-0.35 |

| Iwu AWS | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.20 | 0.04 | 0,030 | ≥0.10 |

| URU Ọmụmaatụ | 0.07 | 0.75 | 0.35 | 1.15 | 0.5 | 0.013 | 0.018 | 0.150 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | IMAPACT URU J/℃ | ELONGATION(%) | |||||||||

| GB/T iwu | 460 | 550 | 730*2 | - | 15 | |||||||||

| Iwu AWS | 460 | 550 | 730*2 | - | 19 | |||||||||

| URU Ọmụmaatụ | 510 | 610 | 730*2 | 180/ Ọnọdụ okpomọkụ | 23 | |||||||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Nkwakọ ngwaahịa:

| NKWUKWU | Ogologo | PCS/1KG | Arọ/1KG | |||

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Ikpe a na-ahụkarị

Asambodo

Ngwaahịa mejupụtara na nrụnye Njirimara iwebata

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S | V |

| GB/T iwu | 0.05-0.12 | 0.90 | 0.60 | 0.80-1.50 | 0.40-0.65 | 0.03 | 0,030 | 0.10-0.35 |

| Iwu AWS | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.20 | 0.04 | 0,030 | ≥0.10 |

| URU Ọmụmaatụ | 0.07 | 0.75 | 0.35 | 1.15 | 0.5 | 0.013 | 0.018 | 0.150 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | IMAPACT URU J/℃ | ELONGATION(%) | |||||||||

| GB/T iwu | 460 | 550 | 730*2 | - | 15 | |||||||||

| Iwu AWS | 460 | 550 | 730*2 | - | 19 | |||||||||

| URU Ọmụmaatụ | 510 | 610 | 730*2 | 180/ Ọnọdụ okpomọkụ | 23 | |||||||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Nkwakọ ngwaahịa:

| NKWUKWU | Ogologo | PCS/1KG | Arọ/1KG | |||

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||