AWS E7018-A1 obere alloy steels igwe ntụ ntụ ịgbado ọkụ waya Ngwa ịgbado ọkụ

Ngwa&Ọkọlọtọ&Ndeeba:

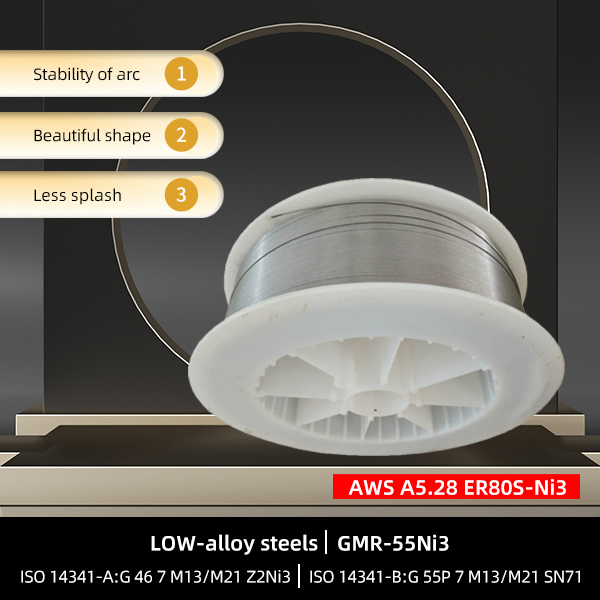

AWS E7018-A1 (R106Fe) okpomọkụ na-eguzogide ígwè aka electrode kwesịrị ekwesị maka ịgbado ọkụ ji esi mmiri ọkpọkọ, okpomọkụ Exchanger kpo oku elu ọkpọkọ na uzuoku anwụrụ n'okpuru 450 ℃ (dị ka 15MoG, T1, P1 ígwè) na ndị ọzọ oge. Dị ka ASTM A204 na A335-P1 tubes; The weldment kwesịrị preheated ka 90-110 ℃ tupu ịgbado ọkụ, na-echekwa interlayer okpomọkụ. Enwere ike iji maka ịgbado ọkụ n'ozuzu obere alloy ígwè elu ike ígwè Ọdịdị. Na nke a aka electrode nwere ike iji maka zuru ọnọdụ ịgbado ọkụ. Dị ka e ji mara nke mmepụta usoro nke obere okpomọkụ liquefied gas, a na-eji obere okpomọkụ ígwè na ọkwa dị iche iche dị iche iche ọrụ okpomọkụ (-40 ℃, -70 ℃, -100 ℃, -194 ℃, -253 ℃). ), na a na-ahọrọ ihe ịgbado ọkụ kwekọrọ.

Atụmatụ

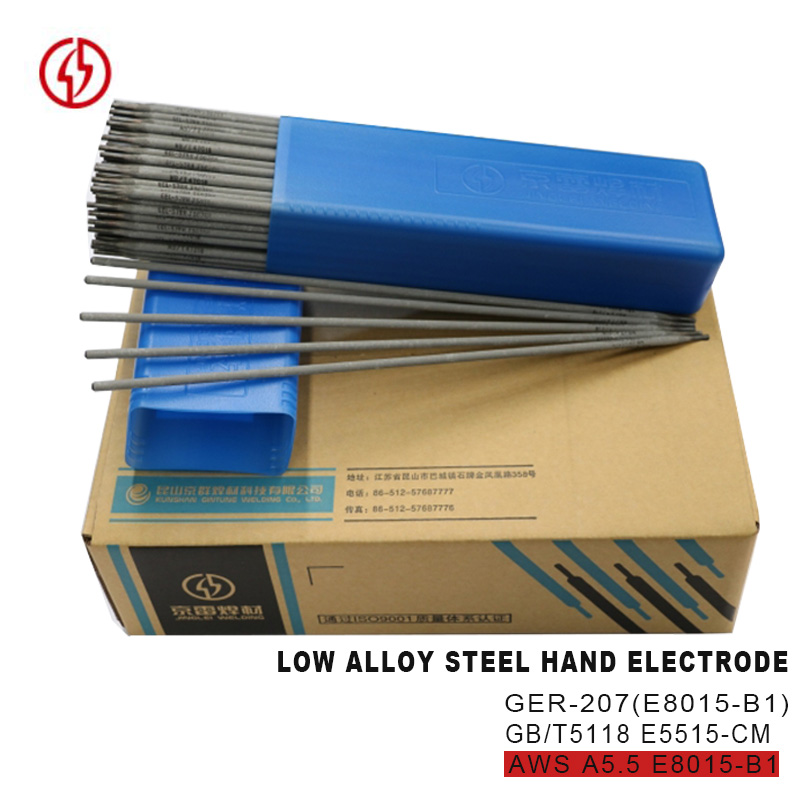

Ụdị aka electrode a bụ ígwè ntụ ntụ obere hydrogen ụdị aka electrode, na-agbakwunye ígwè ntụ ntụ, nnukwu agbaze arụmọrụ; A na-agbakwunye 0.5% Mo iji meziwanye ike weld na nguzogide corrosion; Na arc ahụ kwụsiri ike, ọ na-adịchaghị agbasa, na-akpụpụta, desagging dị mfe, arụmọrụ X-Ray dị mma.

Ihe ndị a na-ejikọtakarị nke pearlitic okpomọkụ na-eguzogide ígwè bụ chromium, molybdenum, vanadium, niobium na ihe ndị ọzọ iji gboo mkpa ọrụ dị iche iche. N'ihi ihe nkwonkwo nke carbon alloy ọcha na ígwè, ọ dị mfe ịmepụta usoro siri ike n'oge ịgbado ọkụ, na ịrụ ọrụ ịgbado ọkụ adịghị mma. Ya mere, nchara na-eguzogide okpomọkụ na pearlitic na-ekpocha ọkụ tupu ịgbado ọkụ ma na-ewe iwe mgbe ịgbado ọkụ.

Ụlọ ọrụ & Ụlọ ọrụ

Ngwaahịa mejupụtara na nrụnye Njirimara iwebata

Ngwaahịa mejupụtara na nrụnye Njirimara iwebata

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T iwu | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0,030 |

| Iwu AWS | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0,030 |

| URU Ọmụmaatụ | 0.6 | 0.7 | 0.31 | 0,035 | 0.5 | 0.012 | 0.01 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | IMAPACT URU J/℃ | ELONGATION(%) | |||||||||

| GB/T iwu | 390 | 490 | 620*1 | - | 22 | |||||||||

| Iwu AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| URU Ọmụmaatụ | 480 | 570 | 620*1 | 170/ Okpomọkụ nkịtị | 26 | |||||||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Nkwakọ ngwaahịa:

| NKWUKWU | Ogologo | PCS/1KG | Arọ/1KG | |||

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Ikpe a na-ahụkarị

Asambodo

Ngwaahịa mejupụtara na nrụnye Njirimara iwebata

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T iwu | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0,030 |

| Iwu AWS | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0,030 |

| URU Ọmụmaatụ | 0.6 | 0.7 | 0.31 | 0,035 | 0.5 | 0.012 | 0.01 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | IMAPACT URU J/℃ | ELONGATION(%) | |||||||||

| GB/T iwu | 390 | 490 | 620*1 | - | 22 | |||||||||

| Iwu AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| URU Ọmụmaatụ | 480 | 570 | 620*1 | 170/ Okpomọkụ nkịtị | 26 | |||||||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

Nkwakọ ngwaahịa:

| NKWUKWU | Ogologo | PCS/1KG | Arọ/1KG | |||

| 2.6mm | 300mm | 48 PCS | 2KG | |||

| 3.2mm | 350mm | 27 PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||