490Mpa Electrode aka maka igwe dị elu

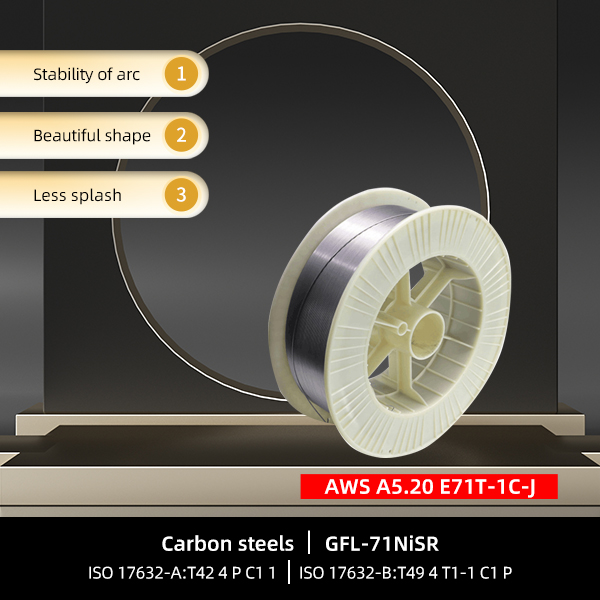

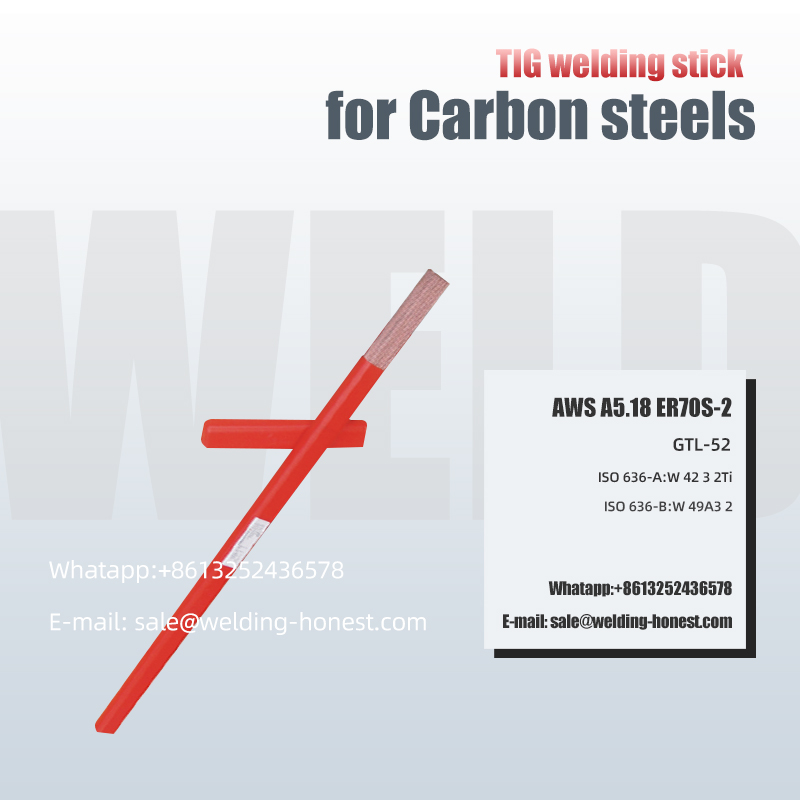

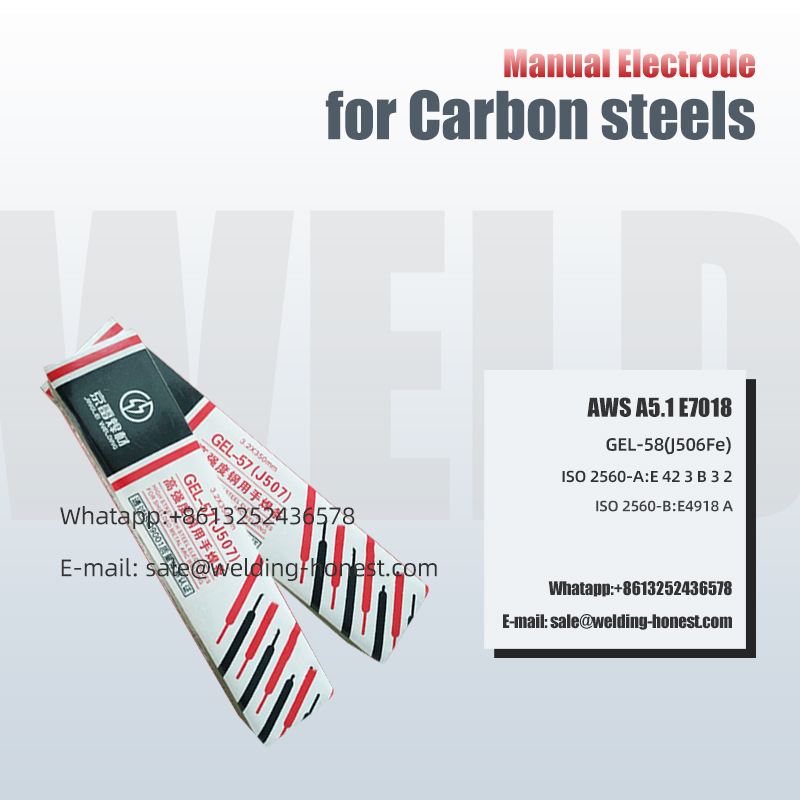

Ngwa&Ọkọlọtọ&Ndeeba

1. Kwesịrị ekwesị maka ịgbado ọkụ carbon ígwè na ala alloy dị ala, yana ike kwekọrọ ekwekọ nke BOILER, pipeline, ụgbọ ala, iwu ụlọ, bridge na ihe ndị ọzọ, dị ka Q345.

2. Ọkọlọtọ anyị zutere: GB/T5117 E5018, AWS A5.1 E7018 & A5.1M E4918, ISO2560-A: E 42 3 B 3 2, ISO 2560-B: E4918 A

Ebe ọ bụ na E7018 electrode na-amịkọrọ mmiri ngwa ngwa, a na-edobe ya na oven ihicha electrode. The electrode echekwara na ikuku nwere ike rebaked na 350 ~ 400 ℃ maka 1h ~ 2h. Iji weghachi ihe onwunwe nke akpụkpọ ahụ. Enwere ike iji igwe eletrọd E7018 na-agbaji nchara dị nro, mana ike weld ikpeazụ nwere ike ọ gaghị adị oke.

Atụmatụ

Iron ntụ ntụ obere hydrogen ụdị electrode aka, elu ịgbado ọkụ arụmọrụ, kwụsiri ike arc, mara mma akpụ, corrugations, nta splash, mfe de-slagging, ezigbo ọgwụ akpụkpọ ọkụ na-eguzogide, ezi stomatal nguzogide. Ngwongwo arụ ọrụ kwụsiri ike, plasticity dị mma yana ịdị ike na-emetụta oke okpomọkụ.

E7018 bụ elu mma carbon ígwè electrode na ígwè ntụ ntụ ala hydrogen potassium mkpuchi. The electrode nwere magburu onwe ịgbado ọkụ usoro arụmọrụ, arc isi ike dị mma, adịghị mfe na-emepụta magnetik bias ịfụ, ịgbado ọkụ onuete akpụ ezi dị ọcha na mara mma, obere ikwommiri, slag dị mfe; The weld metal nwere magburu onwe ma kwụsie ike ala okpomọkụ siri ike na mgbape mgbape. Ac na DC dual ojiji, nwere ike na-ebu dum ọnọdụ ịgbado ọkụ. Njirimara ya bụ na akpụkpọ ahụ ọgwụ nwere ntụ ntụ ígwè, nke nwere ike ibelata ọnụ ọgụgụ nke ịgbado ọkụ. Ime electrode na 350 ~ 400 degrees Celsius maka 1 ~ 2 awa, ma jiri ya mee ihe. N'ozuzu nke a elu àgwà electrode na-eji maka ịgbado ọkụ ụgbọ mmiri ígwè (A, B, D ma ọ bụ E, A36, E36) na ihe dị mkpa owuwu nke ala alloy ígwè nke otu ọkwa nke ike, dị ka ji esi mmiri ọkụ, nsogbu arịa na n'ụsọ oké osimiri mkpọpu nyiwe. wdg.

Ụlọ ọrụ & Ụlọ ọrụ

Ngwaahịa mejupụtara na nrụnye Njirimara iwebata

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T iwu | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0,035 | 0,035 | 0.08 |

| Iwu AWS | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0,035 | 0,035 | 0.08 |

| URU Ọmụmaatụ | 0,075 | 1.17 | 0.5 | 0.04 | 0.02 | 0,007 | 0.017 | 0.009 | 0.01 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | ELONGATION(%) | ||||||

| GB/T iwu | 400 | 490 | AW | 20 | ||||||

| Iwu AWS | 400 | 490 | AW | 22 | ||||||

| URU Ọmụmaatụ | 460 | 555 | AW | 30 | ||||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | |||||

| ELECTRICITY | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

IHE:

H/W: ịgbado ọkụ kwụ ọtọ

O/W: ịgbado ọkụ n'elu-isi

Ikpe a na-ahụkarị

Asambodo

Ngwaahịa mejupụtara na nrụnye Njirimara iwebata

Ngwakọta kemịkal:

| ALOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T iwu | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0,035 | 0,035 | 0.08 |

| Iwu AWS | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0,035 | 0,035 | 0.08 |

| URU Ọmụmaatụ | 0,075 | 1.17 | 0.5 | 0.04 | 0.02 | 0,007 | 0.017 | 0.009 | 0.01 |

ALA nke igwe:

| ALA | IKE (MPa) | IKE EXTENSION (MPa) | Okpomọkụ ℃xh | ELONGATION(%) | ||||||

| GB/T iwu | 400 | 490 | AW | 20 | ||||||

| Iwu AWS | 400 | 490 | AW | 22 | ||||||

| URU Ọmụmaatụ | 460 | 555 | AW | 30 | ||||||

NDỊ AKWỤKWỌ NDỊ AKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊAKWỤKWỌRỤRỤ

| Nkọwapụta DIAMETERS(mm) | 2.6*350 | 3.2*350 | 4.0 * 400 | 5.0 * 400 | |||||

| ELECTRICITY | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

IHE:

H/W: ịgbado ọkụ kwụ ọtọ

O/W: ịgbado ọkụ n'elu-isi